Multilayer 3D Disks Expand Data Capacity

The professional video industry's #1 source for news, trends and product and tech information. Sign up below.

You are now subscribed

Your newsletter sign-up was successful

Karl Paulsen On any given day, it’s safe to state that local, enterprise and cloud storage needs continue to drive the world’s total storage requirements upwards. For a while it appeared “the cloud” was destined to change the complexion of “local” storage— but that doesn’t appear to be the case. At Storage Visions 2015 (held two days before CES in Las Vegas last month), it was evident that most attendees still prefer to keep local storage “under their own control,” augmenting it with the cloud when third-party applications offer those opportunities without further costs.

In support of the enduring local, as well as other, storage needs, magnetic disk drive capacities have steadily increased from 4 TB to 6 TB, and now 8 TB hard disk drives (HDD) are available as 7200 RPM enterprise- class devices. These huge HDDs appear to be feeding not only the cloud, but are being deployed in enterprise data centers as well, and for differing reasons.

For example, in 2013 the HGST (Hitachi) subsidiary of Western Digital managed to squeeze seven 3.5-inch platters into a single HDD for a total of 6 TB using a hermetically sealed, helium-filled chamber. The introduction of helium (He)—which is thinner than air—reduces friction between the drive platters, which in turn decreases heat buildup yielding less power consumption.

In April 2014, Seagate unveiled an enterprise-class 3.5-inch 6 TB 7200 RPM drive, using only six 1 TB platters in a chamber, which is not filled with helium. Seagate’s Enterprise “Constellation ES” SATA drive lists at $600 with a street price in the $425 region; while the HGST “Deckstar NAS,” a SATA III HDD, is street priced around $325.

Note that enterprise drives must meet mission-critical storage and access needs, have higher MTBFs, and are more expensive due to their high performance and long-term reliability capabilities. For comparison, a non-enterprise 4TB drive introduced in 2013 was priced around $180.

BIGGER AND LIGHTER THAN AIR

In September 2014, HGST announced its Ultrastar He8 (Helium 8000GB) SATA Ultra drive with a list price of $1,099 and street price of about $810. The He8 drive is based on mainstream perpendicular magnetic recording (PMR) technology, making it suitable to most applications and environments.

To my knowledge, these drives are not currently being used in commercial or professional broadcast video servers at this time; and are not typically specified in IT-based COTS servers. Nonetheless, these new He drives yield as much as 33 percent less power consumption, making their place in data centers where less power drain and high drive densities mean lower operating costs alongside a reduction in total physical space needed to house equivalent capacity storage systems.

The professional video industry's #1 source for news, trends and product and tech information. Sign up below.

Besides the advancements in He-drives, another dimension in magnetic storage is promising to yield the future “100 TB-drive.” Currently, magnetic-based data storage technologies have what is called a “two-dimensional (2D)” storage medium structure. This structure poses certain restrictions, mostly driven by the physics of magnetic storage.

Up through the mid-2012 time frame, most conventional data storage devices coded data by the magnetization of approximately 35 nanoscale magnetic grains oriented in either of two possible states on media predefined in a magnetic anisotropy (directionally independent) axis. Reading and writing of the data occurs in a binary fashion from a single continuous magnetic layer. To increase data required that the areal density of data storage had to increase, achieved by writing more bits-per-track and more tracks per radial distance.

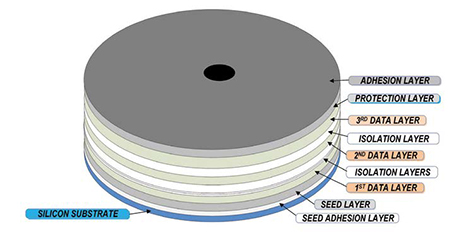

Fig. 1: Multilayer 3D (ML-3D) disk construction FUNDAMENTAL LIMITS

Over the past decade, longitudinal magnetic recording (LMR) technology had reached a fundamental limit for areal densities between 100–200 gigabits per square inch. This limit is termed the “superparamagnetic limit,” which is impacted by a combination of thermal fluctuations in the media occurring at the polarization switch (the change between states) when the disk recording process occurs. This can result in stray fields or improperly aligned polar charges placed on the drive platter—thus the term “bit error.”

To further increase HDD data storage, perpendicular magnetic recording (PMR) was incorporated. PMR was considered a short-term solution, employing bits, which are now oriented in an “out-of-plane” or perpendicular direction versus traditional LMR with its “in-plane” or longitudinal direction. As with LMR, PMR faced media stability and read/write field issues. PMR is predicted to reach its super-paramagnetic limit at about 1 TB per square inch, or five times the limited areal density of LMR.

Two other predecessors to the most recent multilayer 3D technology include thermally assisted magnetic recording (TAMR) or heat assisted magnetic recording (HAMR); and bit-patterned media (BPM). Both technologies still must address nanoscale heat spot allocation and mass production fabrication issues. These technologies are 2D limited and will eventually reach scaling limitations like their predecessor LMR and PMR implementations.

3D RECORDING

Multilayer 3D magnetic recording (ML- 3D) is a developing improvement to spinning magnetic media that is gaining momentum. With its promising opportunities dating back to around mid-2012, researchers at Florida International University published their findings in late-2013 giving evidence that a higher density magnetic storage methodology is attainable.

In ML-3D, instead of having a single magnetic layer (as in the various 2D explanations preceding); the new platter is made up of three magnetic layers (Fig. 1). Insulating layers (isolation layers) are sandwiched in between each magnetic layer. In the conventional 2D disk-platter, a magnetic site is allowed to store only a single bit. In the ML- 3D technology, a triple stack of magnetic layers—each with a uniquely different magnetic site per layer— allows the combination of the sites to store up to 8 bits of data.

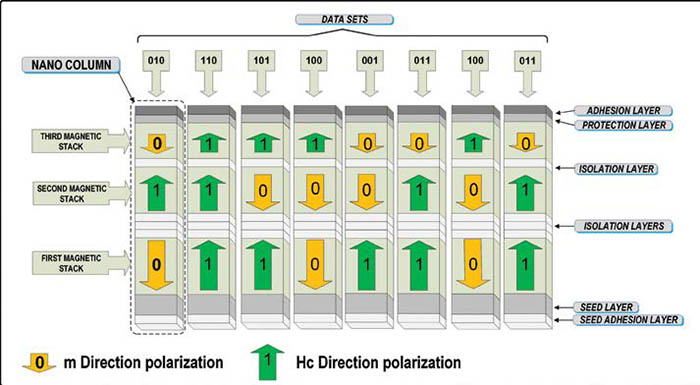

Fig. 2: Data record method and physical components of multilayer 3D (ML-3D) magnetic recording. Each “nano column” is the container for the 3 bit elements that make up a single data word. The data for each word is stored based upon the polarization direction of each magnetic bit for each of the three layers. (Concepts courtesy of Florida International University research project) The magnetization principle aligns bits in a polarity fashion as “north/north/north,” “south/south/south,” “north/north/south” and so forth, per triple site. Each layer of the drive platter has slightly different properties, which can be written to only in a specific type and strength of magnetic field. Fig. 2 diagrams how polarization directions, strengths and alignments can represent each of those data-bits; which are grouped into stacked “nano columns” to create each of the 3D data sets. A special recording head is used to write to the sites on each respective layer. To read the data from the sites, a weakly magnetic head measures the vector sum of the three magnetic fields contributed from each layer.

CHALLENGES STILL AHEAD

Some key challenges still need to be addressed in order for multilayer recording to be completely successful:

Understanding the basic physics associated with recording information in a ML- 3D media, as discussed previously;

The understanding and minimization of the symbol interference caused by the stray magnetic field present from the bulk of a structure (otherwise known as the maximization of SNR); and

The impacts of thermal effects in a 3D device needed to be clarified so as to defer the super-paramagnetic limit.

Since 1957, when the dawn of the practical hard disk drive appeared (as a 24-inch model with a cost of US$34,500); areal density has increased approximately 2.5 million times—as gauged up to the era of the 1TB and beyond HDD. How much we can expect hard disk drives will improve is at best a scientific estimate, with some saying the “60 TB HDD is imminent this decade” (xbitlabs.com, May 2012).

With the ensuing deployments of solidstate (Flash and NAND) storage beyond just the forefront, it will be hard to predict where the SSD versus HDD lines will cross. Equally important in utilizing these higher capacities in better performing storage solutions are the parallel developments in IP-networking and storage-networking technologies. Data systems as a whole must improve incrementally in order to take full advantage of the storage technology advances— whether in the datacenter, the cloud or in your very own broadcast equipment room.

Karl Paulsen, CPBE and SMPTE Fellow, is the CTO at Diversified Systems. Read more about other storage topics in his book “Moving Media Storage Technologies.” Contact Karl atkpaulsen@divsystems.com.

Karl Paulsen recently retired as a CTO and has regularly contributed to TV Tech on topics related to media, networking, workflow, cloud and systemization for the media and entertainment industry. He is a SMPTE Fellow with more than 50 years of engineering and managerial experience in commercial TV and radio broadcasting. For over 25 years he has written on featured topics in TV Tech magazine—penning the magazine’s “Storage and Media Technologies” and “Cloudspotter’s Journal” columns.