Preparing for Your Next Lighting Package—Power Control

Existing lighting infrastructure will need modification to work with new lighting

Unless your studio was built in the last decade, it was almost certainly not designed to support today’s LED fixtures. During the age of incandescent, racks of dimmers supplied power to stage-pin and twist-lock outlets hanging from the grid.

Intensity-level commands were sent from the lighting console to racks of humming dimmers, tucked away in some room where their buzzing modules and cooling fans couldn’t be picked up by studio microphones. These were the trademarks of every lighting system of the last generation.

This type of dimming infrastructure risks becoming obsolete with the arrival of today’s LED lighting fixtures. This column will help you understand what changes must be implemented before the arrival of your next lighting package.

Transitioning From Dimming to Non-Dim Power

You might be tempted to just change the plugs and park your dimmers at 100%. Don’t.

Your existing lighting infrastructure will need some modification to work with the new lights. In evaluating what must be changed, we need to first note the different requirements of incandescent vs. LED fixtures.

Legacy dimming systems were designed to control incandescent lights using a single modulated power feed. Heating up a tungsten filament to the desired degree of brightness is a fundamentally simple way to make light. But things get more complicated when you need to dim a lamp.

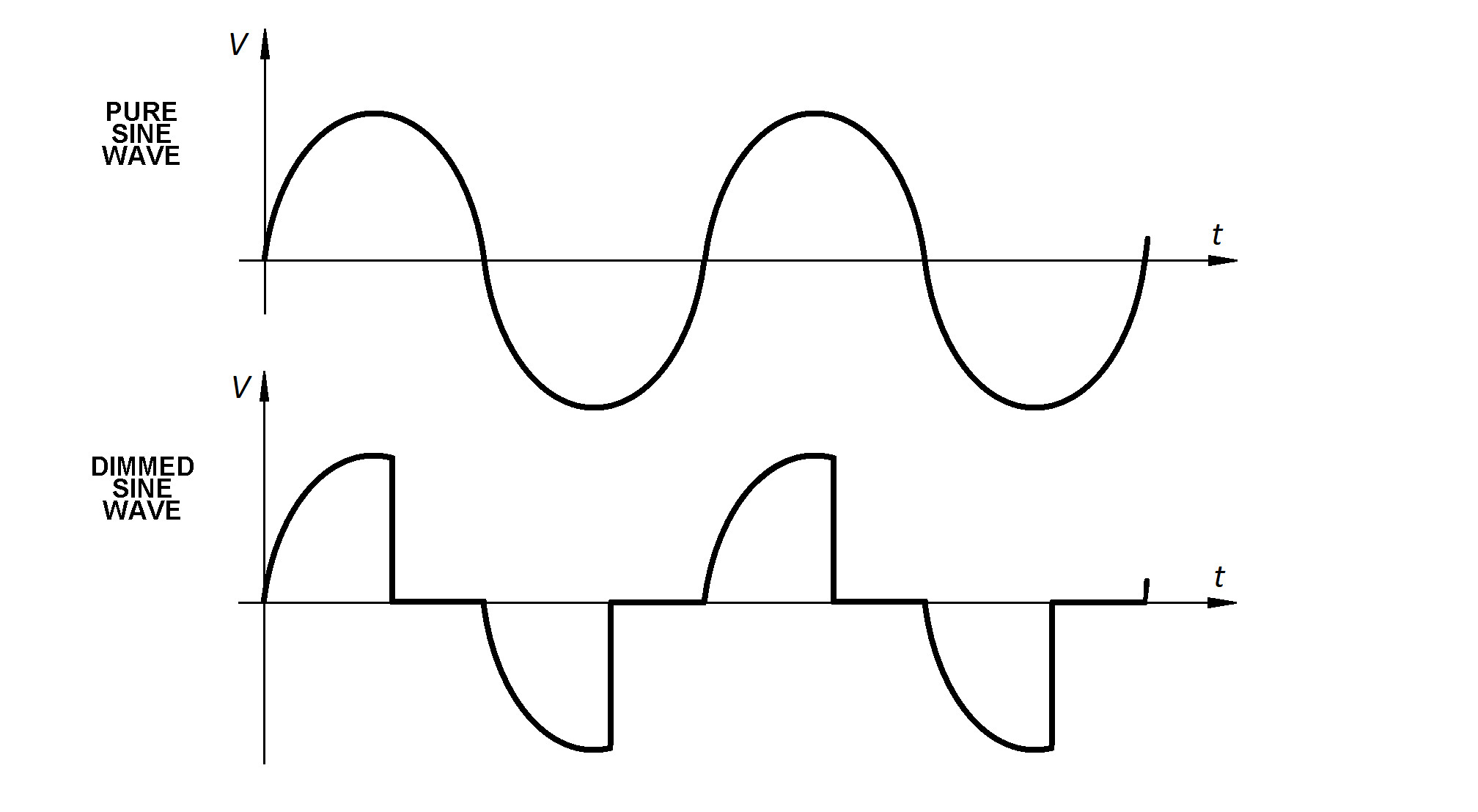

Controlling incandescent brightness was originally done with resistance dimmers—a relatively simple, if wasteful, solution. This method gave way to more efficient modern dimming, which works by “chopping” the power to control intensity. Tungsten filaments were fine with this, thanks to their thermal inertia as a resistive load, but the chopping of the sine wave causes problems for solid-state electronics, such as contemporary LED fixtures.

The professional video industry's #1 source for news, trends and product and tech information. Sign up below.

Solid-state lights require a constant “non-regulated” power source. Dimming is done with on-board dimmers, rather than by dimming the power source they’re plugged into.

A modern dimmer at “full” is not the same thing as a non-dimmed/unregulated circuit. What comes out the back end of a dimming module looks nothing like a pure sine wave.

There’s further distortion of the sine wave, along with wasted energy, from the “chokes,” which helped limit the vibrations of incandescent filaments when they were dimmed (Fig. 1).

Furthermore, some dimming systems used techniques to “goose” or reduce the voltage when the power mains weren’t operating up to standard. All of these modifications to the power create challenges for devices that were designed to be plugged directly into a standard power source.

In short, your legacy dimming equipment may not play well with your next generation of lighting equipment without some modification.

To quote the advice from lighting company ETC, “No matter what type of dimmer you are using, you must set the dimmer to not regulate the sine wave on the circuit that is providing power to the fixture.”

And while your dimmer system may provide an option for something labeled “Non-dim” mode, that’s not always the same thing as “switched.” In fact, “Switched Mode” on some ETC modules still runs through chokes. Naming conventions aren’t standardized or dependable, so verify the actual output with a True-RMS meter.

Getting From There to Here

Your existing electrical distribution infrastructure can almost certainly be modified to work with the new lights, which is always a more efficient choice than running new circuits from scratch. Modifying the electrical infrastructure you already have has the inherent advantage of saving time, materials, and labor—none of which come cheap.

Some dimmer manufacturers offer non-dim/switched-output modules specifically designed for the purpose of passing through the “unregulated” power, as required by the new LED fixtures. Swapping out dimmers for switching modules can be your “plug & play” solution to powering solid-state lights. That only leaves changing the connectors. “Household” (NEMA 5-15) is the typical connector for powering lights today.

Because LED lights are so efficient, multiple fixtures are often run on a single power drop. To help accommodate this, most studio fixtures have pass-through “convenience” outlets. Unlike incandescent fixtures, ganging several lights on the same outlet doesn’t limit individual fixture control because each LED fixture has its own unique DMX address. This feature also reduces the total number of power drops you’ll need to modify.

Even if your dimming system’s manufacturer is no longer in business, it may still be possible to update your system. Any changes should only be undertaken by qualified professionals who understand the system and how you’ll be using it. Any missteps in wiring will almost certainly void your fixture’s warranty. Be careful.

Even with the churn in the dimming industry that’s occurred over the years, you still have some options if your manufacturer is no longer supporting their equipment. One aftermarket service company that specializes in converting dimming systems to non-dim applications is Johnson Systems (www.johnsonsystems.com). They have decades of experience extending the useful life of dimming systems with plug-and-play solutions.

Power Off

There’s an additional advantage in retaining the ability to switch off the power to your lights when they’re not actively being used. As with many electronic devices, they’re never completely “off.”

All new light fixtures continue to use some power in their “standby” state. This not only wastes energy, but causes some additional wear to the fixture’s electronic components.

From the perspective of energy use and reducing unproductive running hours on your lights, being able to turn them completely off is a major advantage.

Transitioning to any new technology can be a bumpy ride, but preparing your lighting power infrastructure to match the needs of solid-state fixtures will help smooth the way.

Bruce Aleksander invites comments and topic suggestions from those interested in lighting at

TVLightingguy@hotmail.com.

Bruce Aleksander is a lighting designer accomplished in multi-camera Television Production with distinguished awards in Lighting Design and videography. Adept and well-organized to deliver a multi-disciplined approach, yielding creative solutions to difficult problems.