12G No Problem for Today’s Cable, Connectors

The professional video industry's #1 source for news, trends and product and tech information. Sign up below.

You are now subscribed

Your newsletter sign-up was successful

ALEXANDRIA, VA.—Years ago, it would have been laughable to suggest that you could send 12 Gbps of data down a coaxial cable for more than a few feet—perhaps two meters—before the signal was lost and unrecoverable. Adding any sort of standard connector to such a cable would also have caused reflections and return loss that would further weaken the signal.

You may wonder just how far you can go with 12G cables, as distances of well more than 100 feet are easily accomplished. One manufacturer states that 100 meters (325 feet) is possible with its modestly sized cable and precision connectors, so 12G cabling is definitely in the realm of the possible.

Now that UHD/4K is becoming commonplace for production, the need to move 12G-SDI signals around a facility is greater than ever. Uncompressed single- link digital UHD (2160p/60) video works out to about 11.88 Gbps, thus the common designation of 12G for the cabling and interconnection components. Getting that capability in a manageable coax cable was not easy.

“The biggest challenge was trying to achieve the maximum transmission distances for each cable without compromising the flexibility of the cable,” said Britton Gensel, a product sales specialist for Canare. “The further the transmission distance, the greater the outer diameter had to be due to the inside dielectric and insulation materials being used.”

When it was clear that 4K/UHD video had staying power and standards were developed defining cable transmission of uncompressed 4K video (such as SMPTE ST2082-1, also known as 12GSDI), there was some doubt that the signal could go more than a few feet on coaxial cable. However, companies had their engineers and R&D labs working on the problem and solved it.

“When dealing with 12G, transmission distance is the key,” Gensel said. “Depending on how far the cable run is should determine the cable type being used. Although our 12G cables are quite flexible and designed for installations, avoiding sharp bends is helpful to reduce any loss. Having the proper connectors assembled on each end also makes a big difference.”

REFLECTIONS AFFECT IMPEDANCE

The professional video industry's #1 source for news, trends and product and tech information. Sign up below.

“The key challenge was reflections that affect impedance beyond 4.5 GHz,” said Steve Lampen, a consultant for Belden. “All our previous cables were tested and verified to 4.5 GHz, to cover 1080p/50-60 Hz [commonly called “3G”]. There were impedance spikes between 4.5 GHz and 12 GHz that affected signal output levels, and it was quickly determined that these were caused by the braid structure. Belden engineers took more than six months to reduce or eliminate these artifacts.”

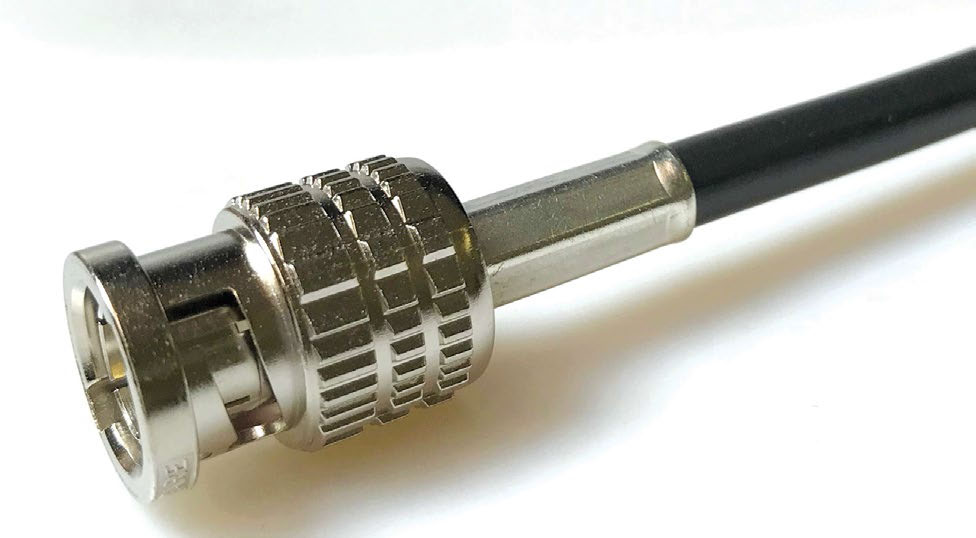

In addition to re-engineering the cable, connectors had to be designed from scratch to permit the smooth handoff of signals at the ends of the cable. Manufacturers such as Belden and Canare supply connectors and installation tools specifically for their cables. (Canare also supplies at least one connector for Belden 4794R 12G cable.)

“Belden has looked at many connectors, including many 12 GHz/4K connectors,” Lampen said. “My suggestion is when you’re talking to a manufacturer or distributor who tells you ‘These connectors are perfect for 4K,’ I would say ‘Prove it!’ Ask for test data, especially return loss data to 12 GHz.”

A few broadcasters and production companies wasted no time when it came to building facilities that incorporated 12G cabling. Jay Nemeth, CEO of FlightLine Films, a Las Vegas-based remote production operator, was approached by one of his aerospace clients to produce webcasts of rocket launches in 4K/60.

“To meet the requirements, we built a 53-foot expando OB trailer that could handle this format,” he said. “However we did not want the extra complexity of quad-link, so we chose 12G. All routers, recorders, production switchers, video monitors and graphics are 12G in our truck.”

Nemeth found that 12G was simply another term for the latest version of what we all know as “infrastructure.” It forms the distribution system, so that all the production devices work just like they have always worked, and it was about as easy to work with as previous cabling standards.

“Single-link 12G makes our workflow as easy as it was with 3G,” Nemeth said. “We purchased 1,000-foot spools of Belden 4794R and installed Belden compression connectors as the truck was built. We also used Belden 1694A for shorter runs. The 4794R is just slightly thicker than standard RG6 cable, and we found it flexible enough to use in most any situation.”

LIKE TO GAMBLE?

Lampen said that it is possible to use a 3G-rated connector on a 12G cable and have it work, but you will be rolling the dice on its performance.

“The only way to know is to get the data or have it tested, or test it yourself—which is expensive,” Lampen said. “Most major broadcasters or installers do a lot of 4K testing. This could save you a pile of dollars in retesting in the field, pulling out and replacing cables, or other time-wasters. The cost of one major install failure would buy or rent all the test gear you need to test everything before you start.”

If you’re concerned that you will need to learn a new technique to mount 12G connectors on 12G cable, you needn’t worry. Canare’s Gensel said that the termination of 12G BNC connectors does not require any special techniques, as they can be easily assembled by using the proper tools.

Of course, fiber optic cables can also carry the bandwidth required for 12G, and more. Fiber is also an excellent way to carry 12G signals over distances greater than can be reached with copper coaxial cable—it’s perfect for getting the signals back from cameras in stadiums or distributing uncompressed 4K from building to building.

As well as fiber works for this application, its function complements that of coaxial cable. Coax can do things that fiber cannot, and vice versa.

“Fiber is great for some things and terrible for others—if you need to go long distance, for example, fiber is the best choice,” Lampen said. “If you need very wide bandwidth (like 12 GHz for instance), nothing beats fiber.”

Lampen then pointed out why copper and fiber will always work together.

“There are two insurmountable problems with fiber,” he said. “First, it works by using photons, not electrons like [copper] cables. So you have to convert from electrons to photons to use fiber optic cables. This is complex and expensive, but time will bring the price down and the bandwidth up. However, fiber will still be only a point-to-point communications medium. Which brings up the second reason: To split an optical signal so that it can go to lots of destinations at the same time, you have to convert to electrons, then split that signal, and convert each one back to photons. That’s even more complex and expensive. Want to make a billion dollars? Invent an optical splitter, or combiner or amplifier, one that uses photons instead of electrons.”

TWISTED-PAIR IP CABLING

Lampen points out that there is another copper solution for distributing high-bitrate digital video: twisted-pair IP cabling.

“The highest bandwidth per pair is Category 6A 10G cable, which is 625 MHz bandwidth per pair [and four pairs per cable],” he said. “And we’re patiently waiting for Category 8 cable, which might be 2 GHz bandwidth per pair. Coax beats that many times over, and fiber optics has even greater bandwidth than coax.

“So why is anyone messing around with data cables?” Lampen asked rhetorically. “Because of the way that IP data centers move and process massive amounts of data is so easy to do in the data world that they are clearly winning this race! It’s not the cable—it’s the structure, the system.”

SDI is a digital distribution standard developed specifically for the television industry, and it has worked well for a couple of decades. IP is a digital distribution standard for the rest of the world, so its market and product development are orders of magnitude greater than what’s done for SDI. As older staff retires and younger engineers and operational staff enter the broadcast industry, they will be predisposed to adopting whatever it takes to move data reliably for the least amount of money.

“So if you think you’re going to design and build a broadcast facility, or video production or distribution business, the way you did it 10 or 20 years ago, you are sadly mistaken,” Lampen said. “You are about to be overtaken by Ethernet, the common language of data centers that is eating up every technological system because it is cheap, reliable and will have enough computing power than for any quality level you want… and it can be delivered. And it will cost a fraction of what those old facilities would have cost, and be infinitely easier to control, to make changes and to upgrade.”

That said, 12G-SDI is here today. Real broadcasters are using it, producing high-quality programming at a cost that is acceptable. For the most part, it works just like SD-SDI did 25 years ago, and it promises to be as reliable as other variants of SDI have been.

You also might also want to consider that SMPTE is already working on a 24GSDI standard. Nothing stands still for long in this business.

If the time has come to integrate 4K/UHD into your system, the cable and connectors you need are here today to do it.

Bob Kovacs is the former Technology Editor for TV Tech and editor of Government Video. He is a long-time video engineer and writer, who now works as a video producer for a government agency. In 2020, Kovacs won several awards as the editor and co-producer of the short film "Rendezvous."