Putting Next Gen TV to the [Full] Test

HUNT VALLEY, MD.—Sinclair Broadcast Group is among the largest stations groups in the United States with 193 stations in some 100 U.S. markets and is also recognized as a frontrunner in the development and deployment of ATSC 3.0. However, there’s been little public awareness of the advanced television testing facility created a few years ago within the Sinclair corporate facility in Hunt Valley, Md.

Tucked away on a lower level of the building, and without much signage to call attention to it, the 1,100-square foot “L”-shaped laboratory was formerly inaugurated in 2016 and is officially known as “ONE Media Labs” (ONE Media is the designation for “think tank” innovations arm of Sinclair). Since its formal inception (and even before) the unit has stayed busy with experimentation by both Sinclair employees and the collaboration of others involved in carving out the road to television’s next generation operating platform.

Marshall Behrmann

Asked about the mission of the facility, Marshall Behrmann, the senior lab engineer, described it as a test bed for virtually anything having to do with ATSC 3.0.

“We perform integration, testing and evaluation of a lot of 3.0 products and subsystems,” said Behrmann. “We also do systems engineering work and interoperability testing—‘plugfests.’ Most recently, we were involved in some extensive evaluation of new software-based Harmonic and Ateme encoder products. We needed to establish the density level in connection with ATSC 1.0 MPEG-2 compression. This is an important parameter as we move into the repack and the addition of extra program streams associated with channel sharing and literally involved months of work.”

OPEN TO ALL OF THE ATSC 3.0 COMMUNITY

Although much of the work involves Sinclair-related efforts, Fred Baumgartner, Sinclair’s director of next-generation implementation, was quick to point out that the facility is open to anyone wanting to perform testing related to the ATSC 3.0 DTV transmission standard.

The professional video industry's #1 source for news, trends and product and tech information. Sign up below.

Fred Baumgartner

“We work with everyone,” said Baumgartner. “It’s very open. If someone wants to come and play, we let them in—anybody with a real business interest in ATSC 3.0. There aren’t a whole lot of barriers.”

(This is very much in line with Sinclair’s proactive part in development and promotion of ATSC 3.0. The company hosted 3.0-related industry plugfests in 2016 and 2017 that involved players from around the world. The number of participants was such that these events were held in the ballroom of a nearby Hunt Valley hotel.)

[Sinclair/ONE Media Host Second ATSC 3.0 'Plug Fest']

Behrmann noted that the lab itself had hosted testing of products from companies including Triveni Digital, DigiCap, Enensys, DS Broadcast, Ateme, Harmonic, LG, Samsung, Sony, CleverLogic and just about every other entity involved in advanced television.

“Anybody can come and use the facility, so long as they clear it with Mark,” said Behrmann, [Mark Aitken is Sinclair’s vice president of advanced technology, president of ONE Media, and oversees laboratory operations.]

‘WE CAN DO ANYTHING’

The ONE Media lab even includes an area for subjectively observing ATSC 3.0 video and audio. It’s been dubbed “the living room of the future.”

The ONE Media lab is chock full of test gear, including ATSC 3.0 signal generators, monitoring gear, precision demodulators, video and audio sources and the sophisticated measuring equipment necessary to create just about any real world or imagined scenario involving digital television and its transmission and reception.

“We think we have the best-equipped ATSC 3.0 testing facility in the country,” said Behrmann. “It’s really second to none. It may be the best-equipped facility in the world, but I haven’t had the opportunity to visit the ETRI facility in South Korea.” [ETRI, the Electronics and Telecommunications Research Institute, is a South Korean research organization that has played a big part in the development of ATSC 3.0. ONE Media and ETRI have been open collaborators and have co-authored many papers advancing the frontiers of NextGen research.]

Asked about how much money was invested in the laboratory, Behrmann said that it would be difficult to come up with an exact figure, as some amount of the gear being used was on loan from vendors, but he estimated that it would take $2.5 million or more to recreate such a facility.

Ian Hoots

“It could easily amount to that much,” said Ian Hoots, who works as a systems engineer with Acrodyne Services, a Sinclair subsidiary that had a hand in setting up the lab. “We have one exciter alone that is worth about $30,000, and when you have at least one of everything, all of this adds up pretty quickly.”

Asked about his part in the operation, Hoots explained that he was there to help with the initial construction, but testing and developmental work was going on even before he arrived in 2016.

“This is where they created the ATSC 3.0 ‘bootstrap’,” he said. “But that was before me. We have the prototype gear—the platform they used for developing the bootstrap—hiding away in our storage cage, but it’s old and clunky now. There’s some real history here.” [The ‘bootstrap’ is part of the 3.0 physical layer and with its fixed sampling rate, signal bandwidth, time-domain structure, subcarrier spacing and other attributes that are known to all receiving devices, and as such provides a universal entry point into the signal to allow its demodulation and decoding.]

[The ATSC 3.0 Physical Layer—Bootstrap Basics]

When asked about taking the bootstrap technology out of storage for a picture, Hoots stated that “there isn’t much to see; just a nondescript ‘black box.’ But we have it just for the sake of hanging on to it.”

(L-R) Behrman and Hoots pose with one of the ONE Media ATSC 3.0 test gear racks.

Hoots said the lab collection also included other 3.0 “relics,” including the earliest of the ETRI/CleverLogic prototype receivers.

“Early on, we had all these ways to transmit bits but zero ways to receive them, so these receivers were quite an important addition,” he said. “As time went on, we got an LG chip-based receiver from DS Broadcast. It’s actually a full IRD.”

THIS IS JUST THE BEGINNING

Asked about the future of the laboratory, now that the ATSC 3.0 standard is complete and the FCC has authorized its transmission, Hoots and Behrmann were quick to respond.

“We’re actually at the beginning of a long journey,” said Hoots. Behrmann recalled a conversation he had with Aitken, when he was asked about leaving his assistant chief engineer’s position at Sinclair’s WBFF Baltimore television outlet to work in the testing lab.

“I had some concerns about leaving my WBFF job and asked Mark how long he thought the 3.0 project would run,” said Behrmann. “He said that even if 3.0 ended, we would be moving out on ‘4.0!”

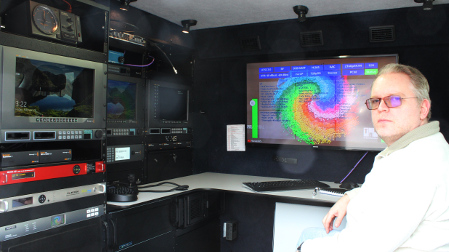

The new ONE Media mobile testing van. It features FCC-calibrated receiving antennas and a very sophisticated system for documenting off-air ATSC 3.0 signal measurements.

TAKING IT ON THE ROAD

Of course, a television transmission system, or any other technology, isn’t of much value if it’s only deployed within a laboratory. Sinclair/ONE Media recognized this early on and is now ready to move their testing and measurement operations out into the real world as U.S. stations begin to transmit ATSC 3.0 signals. In mid-2017, the lab purchased a vehicle to outfit as a mobile test lab and has spent the past six months or so building it out. Bill Soreth, a systems development engineer from Acrodyne Services, has led the effort, working with Behrmann and Hoots to select and load gear into the van and also to develop a plan for ATSC 3.0 field testing work.

“It’s basically an ATSC 3.0 receiving and measurement platform,” said Soreth. “We’ve got the latest CleverLogic and DS Broadcast receivers and RF capture technology that allows us to record the entire RF spectrum. There are two A-H Systems FCC-calibrated dipole antennas—one for vertical plane measurements and one for horizontal plane—on a 30-foot mast, as well as an omnidirectional antenna and a couple of other masts for additional antennas.

“We’ll be using an IMAS [Integrated measurement Analysis System] from AFT for GPS mapping,” added Behrmann. “It takes in all of your RF spectrum and meters it to give you bit-error rates and SNRs, and ties that to a GPS map and then takes a snapshot of that every second.” He added that the van also includes a roof-mounted camera for recording the various paths and locales taken by the vehicle.

“When we finish our drive testing, we can save the data and then take it back to the office for a complete analysis,” Behrmann said.

“We plan to use the truck for a lot of SFN test and measurement work as 3.0 rolls out,” noted Baumgartmer. “The initial drive testing will be largely to validate and adjust the ‘Progira Plan’ software that we using to plan SFNs in several areas.”

Bill Soreth performs a systems check of the gear inside the van.

Right now, this mobile ATSC 3.0 testing facility has only about 1,000 miles on the odometer—largely the mileage from the drive from its Boston supplier, Accelerated Media Technologies, and some practice runs in the greater Baltimore/Washington area for preliminary studies of the experimental 3.0 SFN signals that Sinclair has been radiating in those two markets; but Soreth, Hoots, Behrmann and Baumgartner all expect to see it travel a lot more in the coming years.

[One Media Conducts ATSC 3.0 'Concept' SFN Trials]

“The idea is to get everything right while we’re here in Baltimore,” said Soreth. “Then we start adding the milleage as we crisscross the country to document other markets.”