Light Sources 101: HMIs

The professional video industry's #1 source for news, trends and product and tech information. Sign up below.

You are now subscribed

Your newsletter sign-up was successful

Jay Holben

In the world of luminaries, the carbon arc used to be the king, but his time has faded and left room for the HMI to be king of the power and utility.

HMI is an acronym for hydrargyrum (the Latin for mercury and the basis of the periodic chart symbol Hg) medium-arc iodide. HMI is actually a trademark of Osram GmbH, the original manufacturer of metal-halide gas discharge lamps, but it has been adopted as a common colloquialism for any mercury-based metal-halide fixture.

The conceptual design of a halide gas discharge lamp dates back to 1912, but it wasn’t until the 1960s when the German television industry asked Osram to produce more efficient and less-expensive daylight color sources that the technology was really perfected.

A specialty HMI fixture manufactured by Arri, the 1,800 W HMI — the brightest fixture that can be plugged into standard 20A “household” power. The HMI was introduced in 1972 for the European television industry and quickly adopted by television and film professionals worldwide. They were a little slow to be adopted in the United States as they were designed to operate at 50 Hz and adjustments to 60 Hz, which include modifying the lamp arc to a shorter distance and changes in bulb configuration, took some time.

HMIs use mercury vapor to create light, not unlike a fluorescent lamp, but employ a continual electrical arc, as opposed to phosphor coating, at very high intensity to create a very powerful light. The addition of halide salts helps to define the color and consistency of the light.

HALOGEN LAMPS

A halide is a chemical compound of halogen with an electropositive element. Each halide salt (mercury, AgCl, AgF, AgBr and Agl) glows a different color and the combination of the halides, together with the blue glow of the main mercury arc, help to create the precise color temperature.

The professional video industry's #1 source for news, trends and product and tech information. Sign up below.

HMIs burn at a very high temperature and the gas inside the envelope is at a very high pressure (around 50 psi), which makes them very dangerous when they fail. Safe handling of HMI bulbs is of a paramount concern—not to mention they’re very expensive (as compared to standard tungsten bulbs). HMIs sometimes fail catastrophically and actually explode, but this is a rare occurrence.

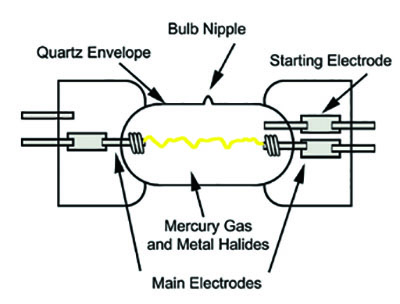

The components of an HMI bulb: Quartz envelope, Igniter, Electrodes, Mercury gas and halide salts, Nipple As with all halogen lamps, care must be taken when handling the bulb. If you touch a bulb with your bare hands, the oils from your fingers leave a coating on the lamp that heats up and actually acts like an acid on the quartz glass. A single fingerprint can cause a lamp to fail. It’s a good practice to clean off a lamp with an alcohol wipe and allow the alcohol to evaporate before starting the lamp.

Double-ended HMI lamps have a nipple— a small extrusion—on one side of the bulb. It is of paramount importance that this nipple face away from the fixture reflector and towards the front of the fixture (not up or down). Any other configuration can cause a reduction in lamp life and a possible catastrophic failure of the bulb.

The HMI lamp is a sealed vacuum with a quartz envelope. The lamp has three electrodes, one that is a starter or igniter; and two main electrodes that form the lamp arc between them. When the lamp is first struck, which requires a high burst of electricity, the igniter sparks between itself and one of the main electrodes, then the arc spreads to the other electrode. It is, initially, very dim.

A battle-scarred 1,200 W HMI Par on the set. The small arc spreads across the gas in the lamp to the other electrode and, at first, the arc fills the lamp until it warms up and starts to get smaller and brighter. As the lamp heats up, the mercury starts to vaporize; then enough heat is made to start vaporizing the halide salts. This is why it takes a few minutes for an HMI to come up to temperature and why you’ll see various colors emitted from the lamp as it does before it finally settles on a clean 5600K– 6000K (depending on manufacturer) daylight color.

VOLTAGE

The HMI requires a ballast to maintain proper voltage to the lamp. Older magnetic ballasts were very heavy, noisy and created a smooth sinusoidal transition in the arc, which caused problems with flicker at various frame rates.

As with fluorescent lamps, the arc itself is actually sparking 60 times a second. We can’t see this with our eyes, but when shooting at shutter speeds of greater than 1/60 of a second (30 fps at 180 shutter angle), the camera will catch moments of the arc sparking and the result will be a flicker in the image. Later electronic ballasts created “flicker-free” HMIs with a square wave that had a very hard transition between on and off to eliminate most flicker problems. At high frame rates, HMIs still have flicker problems, but most electronic ballasts are acceptable for standard use.

HMIs come in a variety of sizes and intensities from 200 W to 18,000 W and have high efficiency, much more so than tungsten, of light output per watt, so they are much brighter than a tungsten at the same wattage—about four times as bright. Typical HMI wattages are 200 W, 400 W, 575 W, 800 W, 1,200 W, 2,500 W, 4,000 W, 6,000 W, 12,000 W and 18,000 W. Note that most of the HMI wattages are different from tungsten wattages (commonly 150, 300, 650, 1,000, 2,000, 5,000, 10,000 W).

Electricians prepare a 12K HMI Fresnel in the basket of a 60-foot Condor crane for an upcoming night shot. HMIs put out a high amount of UV radiation and, therefore, require a UV filtering glass to protect people from the harmful rays. Modern HMI fixtures have safety switches inside them so the lamp will not operate if the UV glass lens is opened.

HMIs come in “open face” (with just UV protective lens), Fresnel, PAR and soft light varieties.

The beauty of the HMI is that it is very efficient in light output, very bright, and it burns at a natural daylight color balance, which means that the HMI fixtures can be used to augment—and even replace— natural daylight. HMIs are often used at night, as well, from high and faraway places—such as a Condor or cherry- picker crane, to light a large area.

Although they are substantially more expensive than their tungsten cousins, HMIs are powerful and versatile tools in your lighting arsenal.

Jay Holben is the technical editor of Digital Video and a contributor to Government Video. He is also the author of the book “A Shot in the Dark: A Creative DIY Guide to Digital Video Lighting on (Almost) No Budget.”