HD Connectivity Presents Challenges

by Joey Gill

PADUCAH, KY. Oh, the excitement! Remember when we first witnessed high-definition images at past NABs, and then later when the HD network signals finally arrived at our stations for retransmission? Most couldn't watch it at home yet, but the picture on the monitor at the station looked great, (and there was also the surround sound.) As time passed, HDTV became affordable and network HD programming became something that everyone enjoyed in their homes.

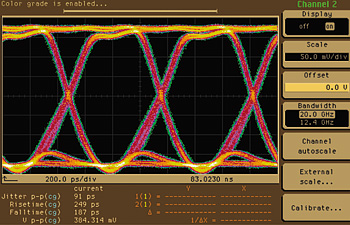

Fig. 1: A SMPTE 292 HD signal at 100 meters 1505a. Courtesy, ADC As HD became the buzz, broadcasters, post house personnel, and field truck operators all read the trades and attended meetings. Broadcasters prepared for it by buying HDTV sat receivers, high stability LNBs, HD servers, HD cameras, HD switchers—the whole shopping list. While the deals were being made, infrastructure was a big topic, and consideration was given to signal path and distribution for this much wider band video.

End of story, almost.

As with most new technologies, after the initial installation, broadcasters got into a comfort zone with HD. However, the first time an emergency signal rerouting had to be made, a change was needed at a studio, or after the first few outings with the new field gear, all of a sudden things may not have been so stable.

Whether using fiber connectivity or copper, dealing with HD signals is a little different from what most broadcasters were comfortable with just a few years ago. With 3G signals (and beyond) just around the corner, the issue of connectivity and distribution will be more important than ever.

HD SIGNALS AND COPPER CABLES

With copper cable, there have always been bandwith limitations. Typically, broadcasters just selected the proper cable for their application. With older analog systems, most cable had enough bandwidth headroom that engineers didn't have to worry much about the radius of a turn, or using cable ties on bundles, or, in general the stuffing of cables into trays. That's not the case any longer.

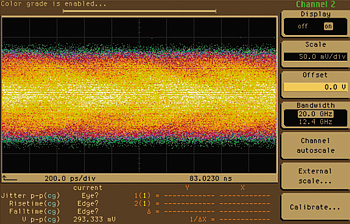

Fig. 2: A SMPTE 292 HD signal at 1 meter 1505a. Courtesy, ADC Dean Rosenthal, market manager for broadcast and cable connectivity products at ADC, a leading connectivity Minneapolis-based manufacturer offered his take on the situation.

"With HD frequencies, you have to be more careful than ever with your cables and connectors," he said.

Rosenthal urges extreme care when securing cable bundles with binding and also when making short turns with cables.

Kip Coates, product line manager for Richmond, Ind.-based Belden Corp., a cable and communications company, says that "cables, connectors, jackfields—everything is critical at HD frequencies and above."

Cable fiber and connector manufacturers stress the importance of not just doing a proper installation, but also following up on the small details as well. According to Coates, digital signals contain low frequency elements that travel down the center of the conduct, as well as high frequency elements that travel on the surface (skin effect). For this reason Belden uses uncoated copper conductors for optimum performance at higher frequencies.

According to ADC's Rosenthal, at HD frequencies and above, differences in connector impedance can create a "brick wall" effect for your signal, (Figs. 1 & 2).

"With a little practice, in most cases you can tell the impedance of a BNC just by looking," he said.

Rosenthal explains that typically the older 58-62 ohm BNCs have Teflon coming out toward the end of the ground plane, while the 72-76 ohm connectors do not. In addition, the back end of the pin is crimped to 0.042-inch instead of 0.068-inch.

Broadcasters are thrifty by nature, but the better solution is to just toss out any connectors, adaptors, or jack fields that you're not sure of.

For path verification at HD frequencies and above, tools such as network analyzers and time domain reflectometers (TDRs) provide the only real solutions. Other methods can display deficiencies. However, analyzers and TDRs can pinpoint the real trouble spots.

FIBER'S ACCEPTANCE IS GROWING

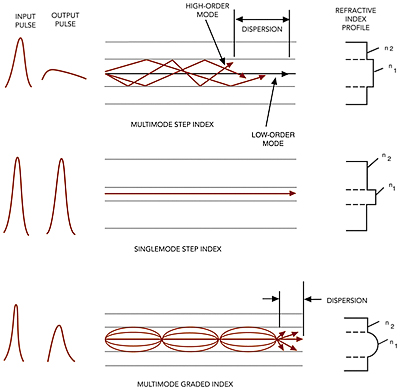

Fig. 3: Overview of fiber modes. Courtesy, Emcore Fiber has a long history of providing point-to-point delivery of very large bandwidth signals. Even when NTSC signals were dominant, broadcasters embraced fiber as a high-quality means for transporting signals. Early on with fiber, connectivity was limited, and cost could be prohibitive for all but the networks. That has changed in almost every community. To refute some fiber myths, fiber is not that fragile, it requires very low power, it's competitively priced when compared to copper, and, according to some in the industry, field service/termination has gotten very simple. Others however, do not always agree.

"Our focus is video over fiber, whether it's SMPTE 259M or 3 Gbps, the demand for point-to-point delivery and switching solutions for high bandwidth video has been increasing steadily," said Alon Dagan, director of operations for Emcore Broadband Video, a San Diego-based fiber-optic equipment manufacturer.

Dagan says that the United States appears to be driving the demand for 3 Gbps, but the demand for high-bandwidth connectivity is strong in Europe as well.

There are two basic types of fiber: the older style multimode and the more modern single mode. Dagan indicates that multimode is OK for shorter distances and certain applications, but that due to its design, there is more reflection and refraction. For the best possible bandwidth and distance, Dagan recommends single mode, (Fig. 3).

Dick Bickford, the national sales manager for Alpharetta, Ga.-based Fischer Connectors U.S., a company that specializes in connector manufacturing, said that repairing fiber in the field has gotten as easy as repairing copper. "Our Unicam fiber connector makes field repairs easy," said Bickford.

An index matching gel in the Unicam eliminates reflection and refraction once the fiber is inserted into the connector, according to Bickford.

"Just remove the cladding, cleave the fiber, and slide it in," he said.

With this new technology, it appears as if the days of grinding, polishing and verifying performance may be over. Bickford said that both terminations and splice units are available.

In dealing with fiber, one of the larger issues for remote production may be the propensity for dust and dirt to accumulate in fiber connector housings. Bickford said that if that happens, it can be catastrophic for signal transfer. He recommends utilizing covers and exercising caution while connecting or disconnecting any type of high bandwidth connector.

Joe Commare, vice president of marketing and international sales for Telecast, a fiber connectivity manufacturer located near Boston, said that Telecast doesn't utilize the quick connectors.

"For our applications, we prefer to have venues pre-configured with quality terminated single mode equipment, near reliable power sources, and in proper enclosures," Commare said "Telecast has played a major role in the recent developments of HD 3D production and transmission, and there are many applications where copper will just not cut it."

He added that Telecast's main focus is in transporting high bandwidth broadcast signals with as little loss and degradation as possible.

"Most issues with fiber have become trivial," Commare said. "I challenge field engineers to put away their ohm meters and pick up a flashlight to check their fiber instead of copper."

The professional video industry's #1 source for news, trends and product and tech information. Sign up below.