3G-SDI: Signal quality is vital

The professional video industry's #1 source for news, trends and product and tech information. Sign up below.

You are now subscribed

Your newsletter sign-up was successful

The use and distribution of 3G-SDI within a broadcast environment has enormous logistical advantages but, along with these advantages, come some real challenges for both engineers and manufacturers alike.

One advantage is the ability to send numerous different video broadcast, production and digital cinema formats down the same wire, but the impact of this on engineers who have to understand all of the complexities of the SMPTE 424M, 425A (3G-A) and 425B (3G-B) when connecting and routing signals is not insignificant. Manufacturers, too, have the challenge of designing broadcast equipment to test all of the possible format combinations of HD-SDI, dual-link HD and 2K, 3-D stereoscopic 2K; color spaces of YCrCb, RGB and XYZ; sampling methods such as 4:2:2 and 4:4:4; and specific data mappings for each format — not to mention the added complexity of alpha channels.

The challenges of 3G-SDI use also have an impact on signal distribution, signal routing, switching, editing and grading. A significant area to take into account when using 3G-SDI is signal quality, which, if out of specification, will have a dramatic impact on the integrity of the data, as well as the ability of broadcast equipment to transparently process the numerous video-format combinations that may appear on the end of the cable.

Signal quality

In the spirit of backward compatibility, HD television formats such as HD-SDI and 3G-SDI were intended to use the existing broadcast infrastructure on humble 75Ω coax. Therefore, they were designed to encode digital video as a single signal that combined serialized data and clock reference. To do this, methodologies such as non return to zero inverted (NRZI) and data scrambling have been employed to ensure that the clock reference can always be recovered/regenerated.

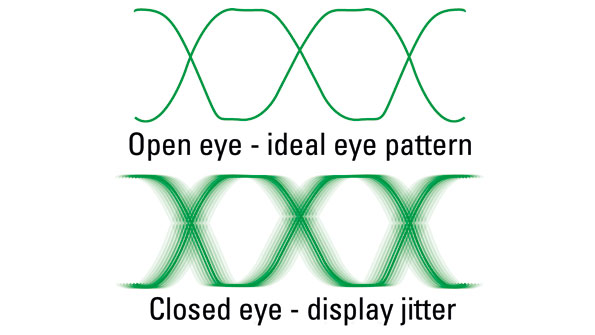

One challenge that engineers in a broadcast environment face is the measurement and monitoring of 3G-SDI signal quality throughout the production chain. The use of high data rates such as 1.485Gb/s for HD-SDI and 2.970Gb/s for 3G-SDI, long cable lengths, and the encoding methods now in common use has resulted in a data transfer that is susceptible to jitter that can corrupt data in a dramatic way. To manage and quantify this susceptibility, measurement techniques using eye-pattern displays have become more and more important.

Figure 1. The ideal eye pattern is a clean waveform. In practice, however, there will always be jitter present in any 3G-SDI signal.

The professional video industry's #1 source for news, trends and product and tech information. Sign up below.

The name “Eye Pattern” is given to the oscilloscope-style display forming the shape of an eye by superimposing multiple clock cycles. The “open eye” is present when monitoring a SDI signal with minimal jitter on a short cable (typically 1m). The eye closes as the severity of the jitter and cable attenuation on the SDI signal increases, as shown in Figure 1.

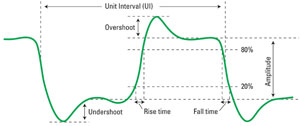

The shape of the signal waveform has a significant impact on the quality, which requires the signal amplitude, rise time, fall time, overshoot and undershoot all to be within tolerance. All of these aspects are affected by cable length, cable type, return loss and cable equalization.

When the SDI data steam is generated or received by a piece of equipment, ideally the leading edge of the SDI clock is aligned exactly halfway through the data sample (i.e. 0.5 UI).

Distribution of the SDI data stream via cabling, infrastructure, repeaters, distribution amplifiers and automatic cable equalizers can cause distortions to the waveform. Poor regeneration of the SDI clock in the receiving equipment may cause the data stream to be sampled earlier or later in the Unit Interval (UI), which in turn will cause the wrong data samples to be taken.

Figure 2. The shape of the 3G-SDI signal is critical to the correct decoding of the data stream and, to ensure this, the critical parameters are defined within SMPTE specifications.

Testing of signal quality should focus on the tolerances defined in the SMPTE 424M specification (see figure 2), which states that when measured at signal source with a 1m cable:

- The signal amplitude should be 800mV ± 10 percent (720mV to 880mV).

- The rise/fall time of the 3Gb/s signal should be no greater than 135ps.

- The difference between the rise time and fall time must not be more than 50ps.

- The overshoot and undershoot must be less than 10 percent.

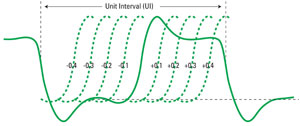

Jitter

The effect of jitter is displayed as faint lines before and after the ideal waveform on the eye waveform, as shown in Figure 3. The greater the amount of jitter, the higher the risk of incorrect data samples being made. The result of incorrect data samples on the program’s video and audio content may be dramatic because individual incorrect bit samples could corrupt whole data words or, even worse, the serial-parallel frame words that define each video line. The loss of individual video or audio samples may be acceptable, but the corruption of metadata may not be because it could affect everything downstream.

The eye pattern can be used to display a range of different jitter artifacts that can be isolated using filters. Jitter occurs when a signal varies in time or amplitude outside of the ideal waveform shape.

Figure 3. The allowable jitter is defined as a proportion of the Unit Interval.

The jitter measurement is quantified as a proportion of the Unit Interval from -0.5 UI to +0.5 UI. The dashed lines in Figure 3 show where this would appear on the eye-pattern display. Testing needs to focus on the amount of Alignment Jitter and Timing Jitter. The worst-case combination is 0.5 UI, which is right on the sampling edge. The SMPTE 424M standard requires that 3G-SDI Alignment Jitter[1] is < 0.3 UI and that Timing Jitter[2] is < 2.0 UI. It can be difficult to make exact measurement of jitter directly from the eye pattern, so instruments that automatically measure jitter are especially useful.

To make sense of the displayed jitter, and to help identify the source of the jitter, it is useful to apply frequency range filters to isolate the different types of jitter that are present. Test equipment can provide a range of filter options that can be applied to the signal before measurement.

Jitter can be caused by a range of different sources, and the artifacts displayed in the eye waveform are typically due to combinations of these at different frequencies and amplitudes. Here are some examples:

- Transmission jitter caused by the equipment generating the video signal. This could include clock phase jitter, amplitude jitter and wander.

- Transfer jitter caused by repeated processing though equipment such as distribution amplifiers and cable equalizers that can introduce additional internal jitter to that already present.

- Receiver phase-lock loop errors in equipment decoding an SDI data stream.

- Data-dependent jitter due to data content that, even after randomization, contains sequences of zeros or ones long enough for the clock recovery/regeneration to drift or lose phase lock with respect to the data.

- Thermal and shot noise caused by the integrated circuits used within equipment that can cause random errors.

- Electromagnetic interference in long cable runs that may be susceptible to the power grid and power switching.

- Waveform distortion due to equipment within the broadcast chain, long cable runs, poorly terminated or un-equalized cables, poor frequency response of cables, or poor equipment return-loss.

Engineers and manufacturers alike face the challenge of dealing with the myriad of video formats that are now possible with 3G-SDI. Testing is needed to ensure that equipment is correctly designed and that all formats are correctly supported.

Forward compatibility

Emerging 2K digital cinema and 3-D production are becoming more widespread, and existing infrastructure may not fully or transparently handle these advances in technology. The ability to inject a specific video format into the production chain and monitor it at each stage can ease the introduction of these new formats, as well as fault-find when things are not working correctly.

3G-SDI T&M equipment has to provide tools to allow engineers and equipment manufacturers to quickly check these emerging formats are supported. “Analog-type” displays (such as picture monitors, vectorscope and waveform monitors) give the engineer an instant view of the decoded data within the 3G-SDI feed to provide a level of confidence that the image data is correct. They decode and display the ancillary data within the 3G-SDI feed to allow the engineer to check its integrity and compatibility with other equipment.

For example, the audio for digital cinema is up to 16 channels of broadcast WAV or uncompressed 24-bit samples at 48kHz or 96kHz.

Stereoscopic television can also employ CIE XYZ color space, 2048 x 1080 pixels; however, it has a frame rate of 48fps (24fps for each eye).

The latest analyzers now support 2K XYZ color space formats and sample rates, as well as 2K digital cinema as defined in the SMPTE ST 2048-2:2011 standard (2048 x 1080 Digital Cinematography Production Image FS/709 Formatting for Serial Digital Interface). 2K test patterns allow “before-and-after” comparisons to be made as 2K material is processed and distributed. The standard test patterns used in HD-SDI test and measurements are now available in the 2K world to allow broadcast engineers to comfortably use their skills in the digital cinema world.

As with HD-SDI, the metadata is a vitally important part of the content of the 3G-SDI data stream and now contains even more complex information that defines the content, mapping and color space information for the material being distributed. An understanding of this metadata is critical to transparent processing (routing, switching, editing, insertion, etc) as well as a method of checking the actual metadata present in the data stream. CRC-based content checking, measured over long periods of time, ensures that no data errors are present in the transmission.

Summary

The testing of 3G-SDI, like all new innovations, takes time for the industry to get to grips with, and will be well-established standard practice just in time for the next round of innovation. The knowledge, skills and experience gained by the industry during the implementation of HD-SDI are directly applicable to 3G-SDI.

The parameters and tolerances defined in SMPTE 424M specification for 3G-SDI are even more critical than those defined in SMPTE 292M for HD-SDI. Therefore, testing of signal quality and compliance is paramount to ensuring correct and reliable functionality.

Footnotes:

- Alignment Jitter refers to artifacts above the specified threshold frequency of 100kHz for HD-SDI signals. Typically video equipment will have difficulty tolerating Alignment Jitter > 0.3 UI which cause decoding errors due to incorrect sampling.

- Timing Jitter refers to a longer-term time-interval error above a low-frequency threshold of 10Hz. Large amounts of Timing Jitter can often be tolerated.

—Alan Wheable is senior technical author at Phabrix.