Light Boxes and Such

The professional video industry's #1 source for news, trends and product and tech information. Sign up below.

You are now subscribed

Your newsletter sign-up was successful

Self-illuminated scenic elements can be a lighting designer's friend. The gamut of devices that can serve as scenic elements goes from a simple bare exposed light bulb to high definition video. I am going to discuss a rather primitive form of this element, a back-lighted diffuse surface, a simple light box.

1000H

Let's assume that we desire a simple panel, part of a wall, to be backlighted so as to appear luminous, maybe even the brightest element in our picture. We try a number of common translucent materials to see if any give the effect that we desire. We take a giant step when we put a piece of tracing paper in our panel and put a spotlight on it from behind.

Some of us recall the rolls and rolls of Clearprint 1000H tracing paper that were used for this purpose, fireproof or not. Looking from the front we discovered that the diffusion properties of the paper are ideal. The light is evenly distributed and we are not aware of the source behind. The amount of brightness that occurs seems more than reasonably available—in fact, it seems very efficient in delivering a workable brightness. We also realize that it is easy to color our backlight source to give a luminous colored surface.

ACRYLIC PANELS

Now that we have established that we have an efficient delivery method, can we find a more rigid and permanent material for our panel? Immediately, we think frosted Plexiglas, the common universal name that has come to define acrylic sheet material. Yes, it turns out that there are a number of rigid plastic products that have excellent diffusion characteristics. We backlight the panel, stick a blue gel in our back lighting spotlight and voila… a beautiful, blue luminous panel. At this point, things go amiss. We turn on our front light and find that if there is even the smallest amount of light spilling on the face of our panel, our beautiful saturated blue becomes a lifeless pale blue and, in some cases, practically white. We know that in order for the color to show, we are forced to precisely focus all our other instruments to prevent washing out our lighted panel—not always simple or practical.

DE-GLOSS

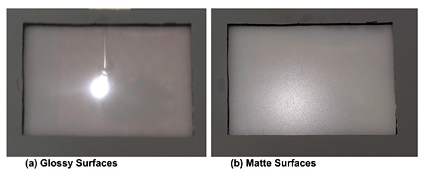

Fig. 1: Two commonly available diffuse plastic panels But we also notice another major difficulty. At certain camera angles, we will "see" our front lighting instruments in the high gloss surface of our frosted Plexiglas. This is certainly not desirable.

The manufacturers of acrylic sheets have been dealing for many years with back-lighting applications as signage, architectural panels, etc. Fig. 1 shows two diffuse plastic panels that are commonly available: (a) has glossy surfaces on both sides, while (b) has matte surfaces on both sides.

Note how the reflected image of the bare light bulb is very apparent in sample (a) but not so in (b). Our choice is then the matte surfaced product. In Fig. 1, (a) is common type 2447 while the more suitable (b) is Acrylite Satin Ice. Both are designated as white. Yes, (b) is more expensive than (a).

GETTING BRIGHTNESS AND COLOR

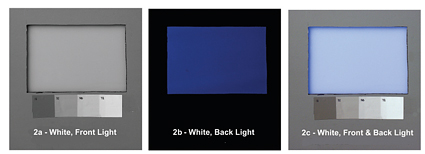

Fig. 2: White Satin Ice plastic sample back lighted with a blue gel in front of the source. Let us return to the more intriguing problem of the washed out color. The problem is, of course, that the frosted plastic is a white surface. Front light on the panel will light up the surface to white before we even try to backlight the panel. So, in the common situation where we cannot control the spill on our light box, we will not be able to control the backlight brightness and, more importantly, unable to get good color saturation.

Fig. 2 shows the White Satin Ice plastic sample back lighted with a blue gel in front of the source under three conditions: (a) is the plastic panel with front light only, (b) is the panel with backlight only which results in a rich, saturated color, and (c) is with a front light added. This results in a very de-saturated color and destroys our luminous quality that we desire.

A SOLUTION

Fig. 3: White Satin Ice has been replaced with a Gray Satin Ice panel to improve color saturation. Fig. 3 illustrates a method to improve the color saturation. We have replaced the white Satin Ice with a Gray Satin Ice panel. [Note: Unfortunately it does not have the excellent diffusion characteristics of the white version of this product. The manufacturer has no explanation for this difference. I had to add a sheet of diffusion, GAM 10-90, behind the gray plastic panel]. This final setup is pictured in three situations. In (a), it is front lighted only and we can see that under this no backlight condition, it shows as a gray, not white. In (b), it is backlight only and adjusted to give the same intensity as the white panel of Fig. 2. Now we add the front light in (c). Notice how the saturation of color has increased over the front lighted white panel of (c) of Fig. 2. I did adjust the intensity of the backlight to compensate for the loss through the gray panel.

GENERAL RULE

Successfully incorporating self-luminous surfaces into a scene can be difficult at times. In the case of LED screens we have the problem of way too much light. But in the case of a light box and similarly, a front projection screen, we have the problem of controlling light on the surface from other sources. In general, in dealing with self-luminous surfaces, the ideal would be that in the "off" condition, as close to black as practical.

In a future discussion I plan to illustrate how to determine the light box fixture requirements.

Bill Klages would like to extend an invitation to all the lighting people out there to give him your thoughts at billklages@roadrunner.com.

The professional video industry's #1 source for news, trends and product and tech information. Sign up below.