Korean researchers develop high-performance bendable Li-Ion battery

The professional video industry's #1 source for news, trends and product and tech information. Sign up below.

You are now subscribed

Your newsletter sign-up was successful

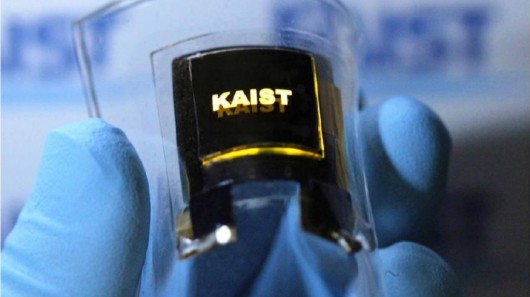

Researchers from the Korean Advanced Institute of Science and Technology (KAIST) have created the world’s first high performance bendable lithium-ion battery.

Using a peel-and-stick type manufacturing process they devised, the new battery provides a constant amount of electrical energy no matter how twisted or deformed the cells become.

The research team, led by Professor Keon Jae Lee from the Department of Materials Science and Engineering at KAIST, developed the flexible solid-state battery, an essential energy source for flexible displays, which drove the battery research. The researchers said the new batteries have a high power density and thermal stability.

Although rechargeable Li-Ion batteries (LIB) have been regarded as a strong candidate for a high-performance flexible energy source, compliant electrodes for bendable Li-Ion cells are restricted to only a few materials, which include organic materials or nano/micro structured inorganic materials mixed with polymer binders.

The performance of these batteries has not been sufficient either, thereby difficult to apply to flexible electronics including rollable displays.

In addition, lithium transition metal oxides used as a cathode electrode have to be treated in high temperature (e.g., ~ 700 degrees for lithium cobalt oxide). It is not possible to anneal the metal oxides, an active material, at a high temperature on flexible polymer substrates.

Professor Lee’s research team recently developed a high performance flexible Li-Ion battery structured with high-density inorganic thin films by using a universal transfer approach. The thin film Li-Ion batteries fabricated on a mica substrate with high annealing temperature are transferred onto polymer substrates through a simple physical delamination of sacrificial substrates.

The professional video industry's #1 source for news, trends and product and tech information. Sign up below.

“The advent of a high performance flexible thin film battery will accelerate the development of next-generation fully flexible electronic systems in combination with existing flexible components such as display, memory and LED,” Lee said.

The research team is currently investigating a laser lift-off technology to facilitate the mass production of flexible LIBs and 3D stacking structures to enhance charge density of batteries.

See a video demonstration.