'Droop'—The New Buzzword In Lighting Technology

The professional video industry's #1 source for news, trends and product and tech information. Sign up below.

You are now subscribed

Your newsletter sign-up was successful

It is only fitting that the intense activity in the lighting world about Light Emitting Diodes should generate a lexicon of pet phrases and buzz words that sends the onlooker to an Internet search. The one that got my attention was "droop." Somehow, it doesn't seem to fit the elegance surrounding the development of LEDs and Solid State Lighting (SSL). From the rather unglamorous sound of "droop," one might assume that it has a negative connotation. It does.

THE PROBLEM

In the beginning, the early developers of LEDs thought that "white" could be obtained as theorized by Sir Isaac Newton—using three primary colors. Unfortunately, selecting three LEDs producing red, green and blue primary colors didn't work as envisioned due to the narrow spectrum produced by each primary source. There had to be a way to fill in the "holes" in the color spectrum when using these narrow spectrum sources. Adding additional LEDs to fill in the voids did result in an improved, but not perfect, white.

Meanwhile, enter the blue "white" LED. Invented by Shuji Nakamura, a well-known scientist in the SSL arena, it is a gallium nitride-based semiconductor, normally used to produce green to violet, as opposed to the more stable and common gallium-arsenide substrate used for red, orange and yellow. He developed a bright blue source and added a yellow phosphor as part of the device that irradiates the blue (like a fluorescent lamp) to create a "white."

Besides producing a more even spectrum distribution, it did it with better efficacy; in many cases, its performance was superior to the performance of a high lumens-per-watt arc source and vastly greater than an incandescent source. Current claims are as high as 250 lumens per watt for a "white" LED as compared to 100 lumens per watt for a fluorescent light source and 20+ lumens per watt for a 3200-degree kelvin studio lamp. The only rub with this "white" LED is the fact that there is a peak at the blue excite wavelength, one that has been shown to be acceptable in practice.

BACK TO THE DROOP

The "droop" appears as we attempt to increase the output of this "white" LED by passing more current through it. We reach a saturation point where the output actually decreases as we increase the energy in the device, and it "droops." As a result, the efficiency goes to pot. This has become a "cause célèbre" in the LED industry, with press releases being issued at a great rate claiming the "droop" has been conquered. It has reached a point where the business section of the "New York Times" recently had a long article titled "Engineers Take Aim at a Barrier in LED Technology." In this comprehensive article, there are a number of illustrations and discussions about "holes" and photons that attempt to explain the phenomenon and are perhaps of interest to physicists. For sanity's sake, I believe these explanations are best left to that group.

Do not despair. Clever and practical fixture manufacturers have helped this restriction by employing a very common-sense design approach. They have wisely increased the number of "white" high-efficiency, lower-wattage devices to obtain the light output that we need, while retaining the efficacy of a high-performance LED. This has provided us with workable fixtures emitting a "white" light that is usable. We will have to wait for the benefits of the single high-powered white LED with a small source size to be used in collimated fixtures until the "barrier" is breached. Hopefully, time will also bring the cost down as manufacturing methods are refined and demand increases.

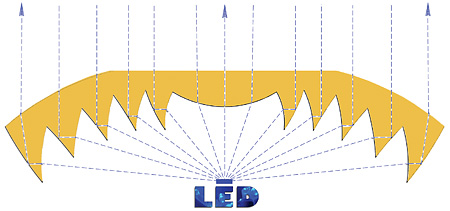

Fig. Diagram of cross section of a collimating total internal reflectance lens (TIR).GETTING THE LUMENS WHERE YOU WANT THEM

In its standard configuration, the LED emitter is actually a flat surface that radiates light in a hemispherical pattern. It behaves like a Lambert surface in that if you observe the brightness (luminance) of the source, it appears as the same brightness from every viewing angle of the hemisphere. As is true of any light source, for efficient utilization of the light output we want to direct the light into a narrower, more concentrative cone; in other words, we want to make the "fixture" as efficient as possible. A traditional light source, as an incandescent filament, delivers its light in a spherical pattern. In many incandescent fixture configurations, we strive, with limited success, to capture the light going out the back of the lamp by means of a reflector that attempts to place this light on the same path of the direct light from the front. Trying to reflect light from the flat emitting surface of an LED is even more difficult than from a filament because it becomes impossible to contain much of the errant rays of light. Coupled with the fact that the light output from an LED is low, this barrier has disheartened fixture designers and users from the outset.

TIR LENS

An interesting method to obtain greater efficiency for sources attempting to create a more directed output (more collimated, if you will) has been the use of Total Internal Reflection (TIR) Optics. The LED surface is fitted with a plastic "lens" that, because of its shape, optically gathers and redirects the light more effectively into a fixed beam angle. The resulting efficiency can double the amount obtained with a simple reflector—with much less light outside the beam. This method has been applied to entertainment fixtures with some success. The downside is that the beam angle is fixed and not adjustable.

The ability to get LED fixtures close to the fixture performance that we are familiar with would still appear to remain elusive. But, then again, there have been successful (and welcome) exceptions that contradict this statement. These exceptions, ones that actually work, give us hope for the future.

Bill Klages would like to extend an invitation to all the lighting people out there to give him your thoughts at billklages@roadrunner.com

The professional video industry's #1 source for news, trends and product and tech information. Sign up below.