Doesn’t Anyone Ever Build Anything Anymore?

My particular rant has been prompted by two almost simultaneous occurrences: (1) I was offered a soldering aid for review for TV Technologyand (2) In connection with the review of a book on the life of TV pioneer Klaus Landsberg for the same publication, I was presented with a number of photos of his early Los Angeles television station. One of the photos was particularly striking—Landsberg is posing with transmitting antennas he apparently constructed for Paramount Pictures’ experimental station, W6XYZ.

This got me to thinking about “the good old days” when the radio or television engineering staff at a broadcast operation was frequently called upon to design and construct equipment for the station. While in some cases, this was a cost-cutting measure and kept otherwise “idle” techs busy (no offense intended); I’m thinking of all the time and talent that could go to waste back in the day when TV transmitters had to have a live “First Phone” operator at their beck and call, and on most days, all he or she needed to do was to turn the thing on at sign-on, take a set of meter readings every half-hour of operation, and then push the “big switch” again at sign-off. There were other similar dull and not-too-demanding personnel assignments too. Fred Baumgartner and Nicholas Grbac in their recent “TV Operations Handbook” really got it right with their characterization of a typical master control operator’s shift as “… fairly boring, punctuated by moments of terror.”

Another, sometimes very strong, reason for “rolling your own” was the unavailability of commercial equipment for the particular application. Either it just didn’t exist, or the lead time for delivery made it an unattractive or impractical proposition to purchase an off-the-shelf unit.

For whatever reason, once upon a time, a lot of people at a lot of stations were involved in building (and designing) equipment for the broadcast plant.

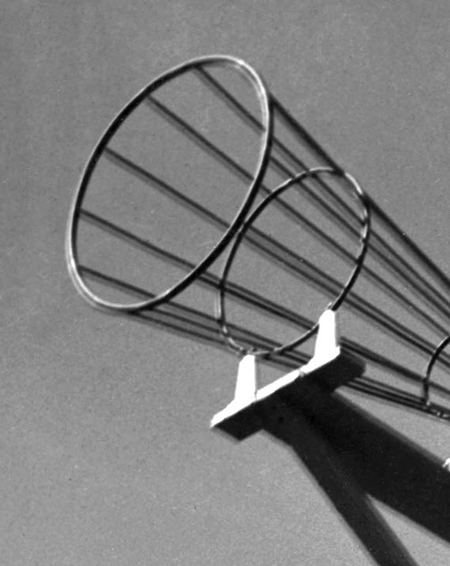

The homebrew visual (upper conical assemblies) and aural (lower split ring dipole) antennas that were used by Los Angeles TV station W6XYZ (now KTLA). It’s seen in this photo on the Paramount Pictures lot, but was later moved to Mt. Wilson as part of the first TV transmitter installation there.

From the John Silva Collection, courtesy of Don Kent

‘WE SHALL MANUFACTURE’

One excellent example of this was the WSM-TV operation. (Tech personnel there once joked that the call sign stood for “We Shall Manufacture.”) The station went on the air with a couple of “homebrew” image orthicon cameras (in addition to the two purchased from RCA), as well as a mostly homebrewed multi-hop intercity microwave linkage to Louisville, Ky., where the station obtained its NBC affiliate feed. (AT&T Long Lines didn’t provide video service to Nashville when the station took to the air.) Not long after the FCC TV “freeze” was lifted in 1952, the staff constructed a linear amplifier to boost the output of their “store-bought” transmitter to the new legal ERP limit of 100 kW. Somewhat later, a full-power VHF transmitter was fabricated on site and saw service for a couple of decades or so before being replaced by a commercial unit. The station also built a lot of its other gear, including transistorized distribution amplifiers. (And from all indications, it appears that the station’s director of engineering, Jack DeWItt, was awarded the first patent for solid-state broadcast equipment gear, a video d.a.)

Other stations and station groups were busy in the workshop also. Back in the early 1970s when Storer owned it, I took a tour of Atlanta’s WAGA-TV and was rather amazed to see the scope of their in-house construction operation, which included production and routing switchers. The station staff was not only constructing gear for WAGA’s use, but also for other Storer operations.

The professional video industry's #1 source for news, trends and product and tech information. Sign up below.

WAGA-TV’s chief engineer at that time, Hugo Bondy, described the scope of his staff’s accomplishments in a “letter to the editor” published in the June 1965 “Journal of the Society of Broadcast Engineers:”

“…we’re building as much of our gear as we possibly can. We can design and build far better gear (in some categories) than we can buy. We can build it for about 20 percent of store costs (assuming that you could buy some of it, which you can’t). It is a good educational project for the crew and sparks up interest and morale.”

Former NBC Television engineering employee Jay Ballard recalled that the “build it yourself” scenario once even extended to network level.

“The guys out at Burbank built a lot of gear for the system—power supplies, d.a.’s, and the like,” said Ballard. “They even used some manufactured modules to construct the audio consoles used in large network productions. Management saw this as a good use of their skills and slack time which might otherwise be spent on personal projects. There was also a financial incentive, as RCA’s broadcast equipment division didn’t offer the network any of the discounts they routinely gave to individual stations and station groups.”

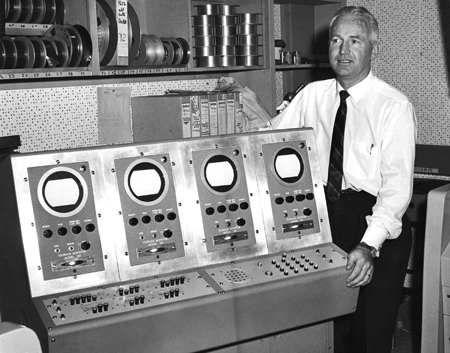

KTLA’s chief engineer, John Silva, designed and built the world’s first “frameaccurate” videotape editor a decade before the advent of timecode. It used four special Hughes Corp. storage CRT units to freeze a pre-determined series of images from the tape, allowing an editor to precisely select in/out-points. It was dubbed the TV-ola and Silva received a patent for his invention. Silva also pioneered airborne TV reporting with his invention of the “Telecopter.”

From the John Silva Collection, courtesy of Don Kent

AN EDUCATION NOT AVAILABLE ELSEWHERE

Bondy was certainly right about the educational aspects of building equipment in house. I was once tasked with constructing a “wipe effects generator” for the production switcher at a TV station where I was once employed. This forced me to do a lot of homework on video switcher and video special effects principles, knowledge that came in very handy later on. Ditto a “split-field” mod for an existing color bar generator, a variable frequency capstan motor power amplifier for an Ampex tape transport, and a number of others. All of these projects proved invaluable in preparing me for what was to come later in my career. (This was especially true in connection with the wipe generator— when I was leaving the station a few years later for a better job, the senior supervisor confided that everyone else on the engineering staff had declined to take on the project before I came along. I was a new hire and went into it with the attitude that it was something I had to do to keep my job! So, in addition to a deep dive into switchers, I received an early lesson in politics.)

HOMEBREW DOESN’T HAVE TO MEAN UGLY

I have to point out that the homebrew gear I saw at WAGA, and other TV operations did not have the appearance of electronic hobbyist or “ham shack” gear. It was almost always well-constructed and attractively packaged and labeled, as witnessed by the accompanying photo of the WSM-TV transmitter.

The homebrew WLW 50 kW “Cathanode” transmitter. Its audio performance bested that from any commercial rig.

Clyde Haehnle

I can’t speak for the TV side of things, but Cincinnati radio giant, WLW, used to fabricate a lot of their gear, even microphones. The 50 kW AM rig designed and constructed by the station’s R. J. Rockwell—though no longer in use—is still a part of the operation’s Mason, Ohio transmitter site and its appearance rivals contemporary commercial gear. (When put into service in the late 1950s, the Rockwell transmitter had better specs than those of most FM stations, allowing WLW to claim that it was “the nation’s highest fidelity station.”

Ballard recalled that the homebrew gear turned out by the NBC Burbank techs consistently performed well and did not look “homemade” in the slightest.

Trade publications, especially Broadcast Engineering, frequently published circuits and construction articles from readers. (The April 1968 BE featured an article on constructing a transistorized sync generator; this was not an “April Fool’s” joke either.)

This surviving example illustrates the quality of workmanship turned out by NB C Burbank technicians. The frame contains d.a.s and a chroma keyer. Date of manufacture is roughly established by the network logo at the top left of each module. It was used between 1959 and the mid-70s.

Jay Ballard

As I mentioned, homebrewing was fun and, at least to me, deeply satisfying. I hold in my own humble way, that there is something vaguely therapeutic in soldering a large number of connections. Perhaps, this is one of the reasons that our industry is having trouble attracting “new blood.” Removing gear from boxes, racking it up and screwing on connectors just isn’t the same as laying out and punching a chassis, or designing a printed circuit board. Granted, the level of sophistication in today’s television infrastructure—as well as the availability of relatively inexpensive off-the-shelf devices—makes in-house design and construction largely impractical. (Any takers on providing a circuit or construction article for a hardware HEVC compression unit, or maybe a UHD camera?)

I have to admit that “store-bought” is undoubtedly the best way to go for most of today’s broadcast equipment, but there are still areas open in the broadcast plant open to “homemade.” And remember, constructing a piece of gear need not be a complete “foundation to rooftop” project where each and every diode, capacitor, i.c. and wire is assembled on your workbench. Marconi’s first radio system was merely a conglomeration of other inventor’s boxes; however, he was the first to string them together and produce a wireless communication system.

I’d really like to hear from you if you’ve been involved in homebrewing gear for your TV station, production house or remote truck. I think many of our readers would be interested too.

James E. O’Neal is TV Technology’s technology advisor, and is a retired television broadcast engineer with some 37 years of experience. He may be contacted atjonealnb@aol.com.