Loudspeakers—Parameters and Design

The professional video industry's #1 source for news, trends and product and tech information. Sign up below.

You are now subscribed

Your newsletter sign-up was successful

Loudspeaker and loudspeaker enclosure design aren’t haphazard processes if done right. Good design encompasses a combination of science, art, engineering and craftsmanship. Simply constructing an arbitrary wooden box and mounting some drivers somewhere on the front panel will most likely not produce optimal results.

As would be expected, the theory and practice of loudspeaker and enclosure design have been continually developing and evolving over the decades since the first loudspeaker was produced and this research is carried on to this day. But a real turning point in describing enclosure design mathematically and predicting performance before screws and glue were put to wood came about in the early 1960s with a paper by A. Neville Thiele, first published in Australia in 1961 and republished in the Journal of the Audio Engineering Society (JAES) 10 years later.

Thiele investigated equivalent circuits of loudspeakers in vented boxes and discovered, according to his paper “Loudspeakers in Vented Boxes,” that “it is possible to make the low-frequency acoustic response equivalent to an ideal high-pass filter, or as close an approximation as is desired.” His method, he wrote, “provided a reasonably precise method of design that was previously lacking.”

A second researcher, Richard H. Small, took Thiele’s ideas (among others) and expanded upon them producing multi-part seminal papers in the JAES in late 1972 and throughout 1973, “Direct-Radiator Loudspeaker System Analysis” and “Vented Box Loudspeaker Systems.”

THIELE-SMALL PARAMETERS

In the first part of the latter paper, Small credited Thiele’s paper as “the first to provide an essentially complete, comprehensive, and practical understanding of vented-box systems on a quantitative level.”

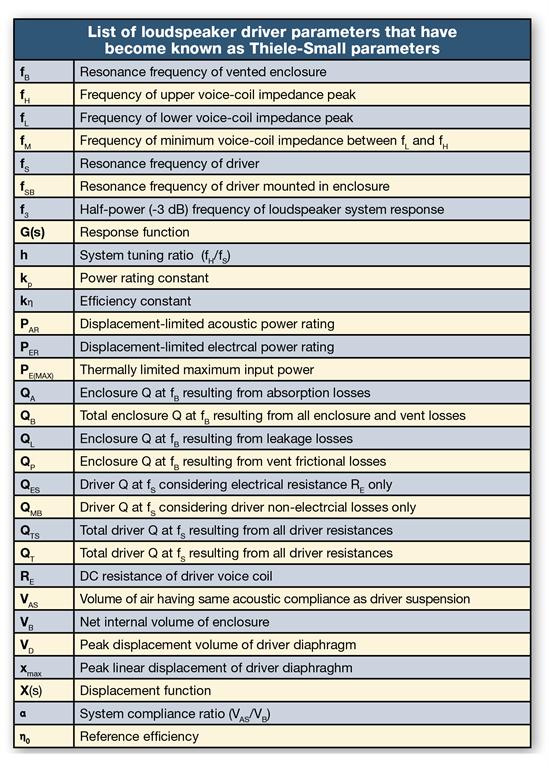

Fig. 1: From “Vented-Box Loudspeaker Systems Part 1: Small-Signal Analysis” by Richard H. Small (JAES June 1973) The Thiele and Small approach began with a certain group of parameters for a given low-frequency (LF) driver. (Their analyses applied to low-frequency response.) These parameters came to be known as, not surprisingly, the Thiele-Small parameters, or T-S parameters for short (see Fig. 1).

The T-S parameters can be measured in the lab—some more easily than others—with both Thiele’s and Small’s papers presenting measurement protocols. Or they can be provided by loudspeaker driver manufacturers who have already done the lab work.

The professional video industry's #1 source for news, trends and product and tech information. Sign up below.

If certain parameters of a LF driver are known, one can then proceed to work through the equations Thiele and Small provided to develop the enclosure design. Or a loudspeaker system manufacturer can work at this from another direction.

If, for example, they have a certain box size in mind and specific acoustical, electrical and physical design goals, they can then work through the formulas to help develop drivers with the appropriate T-S parameters.

According to Thiele, a system that has a good flat low-frequency response down to a predictable cut-off frequency can be designed if the following three parameters are known about a LF driver.

The first is the free-air resonant frequency of the driver. The next, according to Thiele, is “the ratio of electrical resistance to motional reactance at the resonant frequency,” also called the total Q. And the third is the volume of air that has the same acoustic compliance as the driver suspension.

These parameters result from the physical and electrical construction of the driver.

The free-air resonance frequency is measured with the driver not mounted in any enclosure and is a peak in the driver’s LF response. It is dependent on the weight of the driver components that move, like the diaphragm (cone), dust cap and voice coil, and how much that movement is restrained by the driver’s suspension elements like the spider and surround.

The restraining effect of the mechanical suspension on the driver’s motion also factors into the total Q number along with the opposing effect of the electromagnetic (EM) part (the magnet and voice coil) that propels the cone back and forth with an applied signal.

The volume of air parameter corresponds to the stiffness of the driver’s spider and surround.

With these three parameters in hand, the box design can start. We’re not going to go into the formulas, as they are well-documented in the literature, but rather give a general idea of the design process, which is much more detailed than presented here.

THE SIZE OF THE BOX

One of the first things we’d like to know is how big a box is needed. The volume is calculated using the volume of air and total Q parameters. This is the actual volume of air needed in the box to create a maximally flat high-pass filter. The actual size of the box will be larger than this volume to allow for the space taken up by such items as the drivers, support bracing and the vented port. The volume of these items should be added to the calculated volume to give the total volume of the enclosure.

It’s up to the designer to determine the length, width and height of the box that provides the calculated volume. That’s where a lot of the art of design comes in. In his paper, Thiele suggested using ratios that would be used in good acoustical room design.

Another point that Thiele made is that “the box volume is closely proportional to the inverse square of cut-off frequency, which can be varied over a wide range.”

Since the box will act as a maximally flat high-pass filter, it will have a LF 3 dB down point. That value is calculated using the free-air resonance of the driver and the total Q. These two parameters are used in a different equation to obtain the resonant frequency of the box.

As might be expected, a larger LF driver will require a larger enclosure and have a lower cut-off (3 dB down) frequency.

Now we turn our attention to the port. Small’s paper on vented box design provides guidelines for the area of the vent (port) and the diameter of a circular vent so that peak air velocity through the vent will be limited to avoid air noise. We don’t want any air whistling or rustling through the tuned port.

Knowing the inside radius of the vent, as well as the box resonant frequency and box volume, the duct length can be calculated. Settling on a port size and duct length can be an iterative process as can be the design of the box itself.

Mary C. Gruszka is a systems design engineer, project manager, consultant and writer based in the New York metro area. She can be reached via TV Technology.