PART 2

Welcome to part two of our look at audio control room acoustics and the reasons we expend so much effort to build great sounding rooms. In part one we looked at how low frequencies and reflections behave in both large and small rooms. This time we’re going to take a high-level look at the topic of isolation and see that it is the foundation upon which audio control rooms are built.

NOISE SOURCES

Isolation is primarily concerned with making rooms quiet through noise control and it depends mostly on mass. It’s also the area of control room design that gets the most scrutiny when a project is proposed because proper isolation of some spaces can be costly. The noisier the environment, the costlier and more invasive it will be to properly isolate the room, but without proper isolation the mix engineer may not be able to tell whether what he/she is hearing is a part of the mix or part of the environment.

There are certain situations, such as television mobile units, where there is little that can be done because the environment is always going to be noisy. Similarly, some live audio mix rooms will have high levels of acoustic noise, not entirely from the equipment, but from the communications that are necessary during a live event. Mix engineers for live sporting events are seemingly bombarded with noise from every direction, but they still need the ability to turn it all down, tune people out, and focus on listening if audio issues crop up.

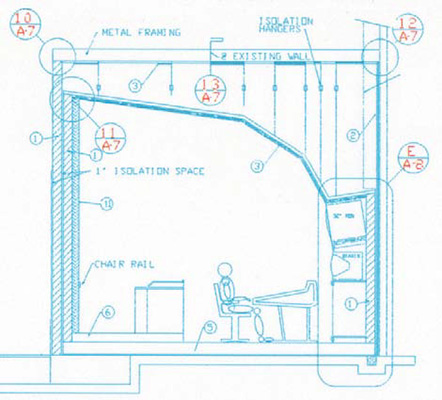

Room planISOLATION

External noise sources include not just sounds made acoustically, but also those transmitted through floors, walls, ceilings and mechanical systems. To properly isolate the audio control room, noise from all of these external sources must be minimized or eliminated. However, isolation isn’t just about keeping noise out of the control room; it’s also about minimizing leakage into adjoining spaces. This is especially important when other production spaces are adjacent or nearby because the sound leaking out of the audio control room could interfere with work in other rooms.

High-end audio control rooms are designed with isolation in mind and are perfect studies in noise control. These rooms are actually built as a room within a room, with the outer room’s floor and thick walls connected to the building, and an inner room that is separated by an air cavity. This room-within-a-room design is excellent for isolation and noise control, but requires more physical space, so they are rare in today’s television production facilities where space is always at a premium.

There are also hefty construction requirements. The inner room sits on a floating floor designed to eliminate noise transmission into the room through the building’s structure and requires pouring two floors, one on top of the other, with a layer of isolating materials between them. The solid ceilings of inner rooms are suspended from the outer ceiling by isolators and inner room walls are attached only to the floor and ceiling of the inner room.

The professional video industry's #1 source for news, trends and product and tech information. Sign up below.

Floating floor levels This method of construction isolates the outer and inner room from each other because most surfaces are physically separated, and some form of isolator separates surfaces that must meet. Of course cable troughs and pipes do penetrate the space, but they include insulators to help avoid bridging the rooms.

The ultimate goal of this design is to achieve minimal leakage of sound through the control room’s structure, and an acoustically quiet space with a low-noise floor (around 30 dBA for a quiet control room). Construction documents call for walls in audio spaces to target a sound transmission class (STC) rating, which rates sound transmission loss through walls, doors and windows. STC ratings are based on frequencies concentrated in the range of human speech (125 Hz to 4 kHz) rather than the full spectrum of frequencies that will be heard in the control room. Architects and construction foremen are familiar with it, and can purchase materials and components with this rating, so it’s a good reference to work with.

Windows and doors in the control room need to have as close to the same STC rating as the walls, which means doors will be heavy and come with special seals and windows will have multiple panes of glass. This allows everything to function as a unit, preventing a similar amount of sound transmission from the entire room.

HVAC SYSTEMS

Requiring just as much forethought as the room design is the design of the HVAC system. The systems that contractors install every day usually do not work well in audio control rooms because they tend to have small rectangular ducts with sharp right angle bends, a design that creates turbulence and noise in the system. We want to avoid either acoustical or mechanical noise from the HVAC system since we’ve gone through so much trouble to make the room quiet.

Some of this noise can be reduced by locating the mechanical components far away from the control room, installing vibration isolators where the unit mounts to the building, or placing the mechanical components in an acoustical enclosure. The system should be designed to be high volume, low velocity to minimize turbulence. Ducting should be large in diameter, flexible, round if possible, and some can be lined with acoustic material if additional soundproofing is required.

It is also critical, when designing the control room HVAC system, to make sure it does not bridge into a noisy space since there could be transmission from that space through the ducting.

That wraps up our quick look at isolation. There’s not nearly enough space in this magazine to go into it in depth, but I find exercises like this to be a helpful reminder of why we expend so much effort when building audio rooms. In the third and final installment of this series, we’ll look at the importance of room size and finish up with practical tips for working with small spaces and tiny budgets.

Jay Yeary is not an acoustician, but has spent many years building audio rooms, trying to make sure they give mix engineers the accurate listening environment they need. He can be reached through TV Technology or via Twitter at @TVTechJay.