OPTICAL STORAGE for HD video acquisition

The professional video industry's #1 source for news, trends and product and tech information. Sign up below.

You are now subscribed

Your newsletter sign-up was successful

The evolution of recording media continues to keep pace with the increasing storage capacities and transfer rates needed for HD video acquisition. One of the two major nontape recording platforms used in today's broadcast facilities is optical storage. Here is a tutorial on how the technology works.

Dual-layer blue laser

Increasing the capacity of current recordable and rewritable blue-laser discs, employing a 405nm wavelength to write/read to a 120mm disc, can be accomplished in a few ways. Physically speaking, the track pitch can be made narrower to increase the overall length of the track (pregroove) that spirals out from the center of the disc. Another choice is whether to adopt land-groove recording or groove-only recording. A third option is to decrease the recorded mark size, enabling more marks along the linear track.

As for the format, a compression algorithm with a higher compression ratio can be employed. The practical solution is to add record layers to the media, effectively doubling the capacity with the addition of each successive layer. Additional layers on opposite sides of the disc, though, require two pick-ups to access both sides or the use of a flipper to turn over the disc to write/read to the opposite side.

Obviously, the use of two record layers on the same side makes more sense. However, that would require the outer-most record layer to have transparency so the inner-most record layer can be written to and read from by the laser. It must also have record layer properties necessary to store amorphous (low reflectivity) marks and crystalline (high reflectivity) marks.

Hence, two new developments were necessary to facilitate dual-layer recording. The first is a semitransparent record layer, and the second is a grooved transparent spacer layer, or the layer that separates L0 layer and L1 layer.

Semitransparent recording layer

The professional video industry's #1 source for news, trends and product and tech information. Sign up below.

Typical rewriteable single-layer discs reflect about 16 percent of the 100 percent incident blue-violet laser light back to the drives pickup. The record layer absorbs 84 percent and uses it to write the signal. Dual-layer relies on only 5 percent reflectivity from both L1 and L0 layers to achieve a reliable read process.

In Figure 1, the optical block, which consists of the laser diode and optical lens, physically moves as one to focus on L0 or L1 layer. The laser first writes to L0 layer radially, from the inside of the disc to the outer circumference, then to L1 layer, from the outside in. This is the movement of the optical block when continuously recording data.

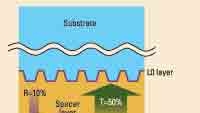

L1 layer absorbs 45 percent of the light, reflects 5 percent of it and transmits the remaining 50 percent to write to L0 layer. Thus, L1 layer is said to have 50 percent transmittance. Because L0 layer reflects back only 10 percent of the light, and L1 layer has 50 percent transmittance, 5 percent of the original incident light is ultimately received by the pickup from L0 layer.

Grooved transparent spacer layer

With single-layer optical disc manufacturing, a pregroove is stamped into the substrate, incorporating a wobble method to allow the laser to track properly on the groove. When two record layers are present, as is the case with a dual-layer disc, a groove must also exist in the second layer (L1 layer) to facilitate proper tracking on this layer as well. To accomplish this, after L0 record layer is applied to the grooved substrate, a 25µm-thick transparent spacer layer is spin-coated on top of it.

A soft stamper, embossed with the same groove pattern as was originally stamped in the substrate prior to applying L0 layer, is pressed down on the transparent spacer layer to create the pregroove for L1 layer. (See 2A in Figure 2.) The spacer layer is then cured using an ultraviolet lamp. (See 2B in Figure 2.) Once cured, the soft stamper is peeled away. (See 2C in Figure 2.)

It is important to note that not only does the spacer layer need to be transparent to enable the laser to write and read L0 layer during normal use, but the stamper must also be transparent in order for UV light to pass through it during the manufacturing process. L1 record layer is then applied to the grooved spacer layer. Both L0 and L1 layers now have the same groove structure with opposite spiral. These additional steps in the manufacturing process and the development of a transparent spacer layer and soft stamper are used in the manufacturing of dual-layer discs, including the Sony Professional Disc. (See Table 1.)

Conclusion

Advancements in manufacturing techniques and layer composition that support both transparency and reflectivity were necessary to bring dual-layer optical disc technology to fruition. The result is a storage/recording media with a capacity more than 70X that of the standard compact disc, yet relies on the same size disc.

Considering the data-intensive nature of HD recording, it is no surprise that this medium, capable of recording such a high bit-density-per-square centimeter in a low-cost, easy-to-handle, reliable and rewritable form, continues to be accepted as an alternative to tape for both HD video acquisition and archive applications.

Wayne Desmond is the national training manager of Sony's Media and Application Solutions Division.