Fiber fundamentals

Why is fiber fundamentally important? Bandwidth. As data rates increase for applications such as HD, 3-D and 4K (or UHDTV, as it is also known), so will the need to transport that data from cameras to trucks and then studios and throughout facilities. Traditional coax has been the primary method of transport, but fiber has properties that are essential as we move to the transportation of higher data rates.

To start, coax cannot go the distance. The maximum distance that a 3Gb/s signal can travel on coax is 100m, whereas the distance 3Gb/s can travel over fiber is more than 35,000m. That’s huge.

There is also weight to consider. For example, 100m of TAC2 fiber can support two camera feeds, return, stereo audio, gunlock, Ethernet and more. The fiber needed for this would weigh about 6.2lbs. To get the equivalent support in coax would require three coax and four copper audio wires, which would weigh approximately 124lbs.

Then, of course, there is speed and bandwidth. Fiber can accommodate high speeds, virtually limitless bandwidth and multiple signals on one cable. Fiber also benefits from immunity to electromagnetic interference. Coax is susceptible to interference, has a maximum speed of 3Gb/s and can only carry one signal per cable.

How fiber works

Fiber-optic cables are essentially a “light pipe” of flexible glass (silica) or plastic fibers that guide light as it passes through at high speed.

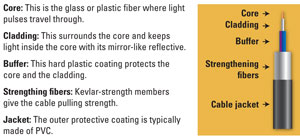

A fiber cable is made of five elements: core, cladding, buffer, strengthening fibers and a jacket. The core is the actual optical fiber and is surrounded by cladding that keeps the light inside. These two elements are encapsulated within a buffer, which is a hard coating that protects both core and cladding. Covering the buffer are strengthening fibers that give the cable pulling resilience. Finally, the cable is fitted with a PVC jacket as further protection. (See Figure 1.)

The professional video industry's #1 source for news, trends and product and tech information. Sign up below.

Figure 1. A fiber cable is made up of five elements beginning with the core, where light passes through, out to a jacket normally made of PVC.

Fiber cables can be single cables (one fiber per cable), or they can be bundles of up to 24 strands, which are quite useful for infrastructure applications. For fixed infrastructures, air-blown fiber speeds up installation considerably. What used to take four to six people eight hours to install now only requires two people and about 30 minutes.

For field productions, hybrid cables, which combine fiber, copper and tactical cables, are important. Hybrid cables combine fiber and wire in one jacket to allow power to accompany the fiber cable for applications that require it, such as cameras. For these applications, SMPTE has defined a standard cable known as SMPTE 311M.

Tactical fiber is amazing and can withstand being driven on by trucks, dollies and cranes. It can also be bent, hung over the edge of a building or crushed. Or, you can slam cable in a door or bend it to a point where light cannot pass. Even then, you only have to release it, and the picture pops right back.

Fiber connections

There are many different connectors for fiber. Small, single-fiber connectors such as FC, ST, SC and LC are the most common and are best for protected infrastructures. In harsher broadcast environments, connectors such as MX or Delphi, which are rated for military conditions, work well. When you are using hybrid fiber, you can use SMPTE 304 (Lemo) or OpticalCON (Neutrik) connectors, which have both copper and fiber contacts. SMPTE 304 can handle the higher voltage of broadcast cameras, but isn’t as strong or easy to clean as OpticalCON. Neither hybrid option is as reliable as a fiber-only solution because copper and glass react differently to extreme temperatures, as well as to being bent and stretched.

An MX “expanded beam” connector makes connections easier because precise alignment is not as critical. Plus, the MX is not as susceptible to dust because lenses inside magnify and refocus the light beam down the connector, which makes it less likely to be obstructed. It’s similar to the difference between using your index finger to block light from a laser pointer and doing the same in front of a car headlamp.

Figure 2. In a multimode setting, light waves travel down the fiber on different paths.

Single-mode vs. multimode

Single-mode versus multimode is the most misunderstood concept when talking about fiber. Multimode means light waves, after leaving the laser, bounce down the fiber on different paths. (See Figure 2.) This is due to the 62.5µ diameter of a multimode fiber, which means that photons arrive at varying times (which is not good for HD television).

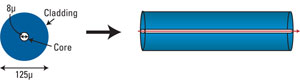

Single-mode fiber was developed much later than multimode, and it has a much smaller radius of 8µ. (See Figure 3.) This enables light to travel straight down the fiber, thus incurring less loss and allowing increased bandwidth to be carried. At distances greater than 500ft, single-mode fiber is the only option for HD/SDI.

Figure 3. Single-mode fiber was developed after multimode and has a much smaller width. The smaller space enables light to travel a straight path.

Does fiber have issues?

Issues with fiber are more related to system design than fiber itself. Fundamentally, the presence of dirt and lack of appropriate power are common challenges. Fiber is susceptible to dirt at the points of connection. Particles can scratch connector ends as well as absorb light. That is where expanded beam connectors mentioned earlier are useful because they are much more forgiving.

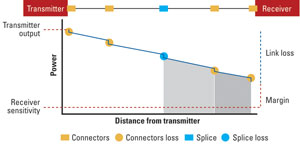

Power budget calculations are needed to ensure that links do not exceed a “link budget,” which is the output power of a transmitter minus the maximum receiver sensitivity. (See Figure 4.) Splices, patch points, patch cables, dirt, connectors at each end of the fiber and the fiber cable need to be factored in when designing a facility’s power requirements.

Figure 4. A power budget calculation (output power of a transmitter minus the max receiver sensitivity) helps ensure that links do not exceed a link budget.

Applications, appetite for fiber are growing

As data rates increase to support 4K and beyond, so will the appetite for fiber. There are great applications for fiber, including ENG, SNG, live events and sports. An outside broadcast vehicle particularly will enjoy noticeable economies on fuel and setup times, with no compromise on the ability to move high-quality video.

Without fiber, the number of cables required to pass standard signals, including video, audio, data and Ethernet, would be well over 80 cables. However, the exact same signals can be muxed onto a lone three-strand fiber cable.

Fiber can also be used in production studios and intra- or inter-facility transport, which is increasingly important given the interest in 4K. By transitioning to fiber now, a facility will be prepared to support increased bandwidth as video bit rates increase on the path to 4K and beyond. In short, your facility’s future is in fiber.

—Sara Kudrle is product marketing manager, Miranda Technologies.