Quantum Dots Connect New Display Technology

QD Vision’s John Ho holds a tube of the finished polymerized quantum dot material that promises to revolutionize the way we see televised color.

ALEXANDRIA, Va.—Even though quantum dot technology goes back the 1980s, it’s not exactly something you’ll find in every household just yet. However, if this year’s Consumer Electronics Show is any indication, the terminology will soon be just as ubiquitous as LED, LCD CFL, CD ROM and countless other technologies that have moved directly out of the lab into big box stores, and ultimately into the homes and hands of consumers.

The show signs shouting: “UHD,” “curved screens,” and “bendable displays” that have appeared on the show floor in the past few years are now being joined by placards proclaiming: “powered by quantum dots,” “quantum dot enabled,” and the like. As the demand for bigger screens, sharper pictures and better color continues, quantum dots seemed destined to play larger and larger roles.

WHAT IS A QUANTUM DOT?

A quick answer is that it’s a very tiny semiconductor crystal; one that’s so small it exhibits behavior described by quantum mechanics.

As explained by John Ho, advanced development manager at QD Vision, a Lexington, Mass., company that manufactures large quantities of such crystals:

“Quantum dots are very simply nanocrystals that are made out of semiconductors, and are invisible to the naked eye because of their size,” said Ho. “And they can emit light—very, very pure light. They don’t scatter light and would be transparent if you put them between sheets of plastic.

Get the TV Tech Newsletter

The professional video industry's #1 source for news, trends and product and tech information. Sign up below.

“They are anywhere from two to 20 nanometers [across]. When you have those sizes, you actually have quantum mechanic effects, like a spring in a box. If you shrink the box, the spring is compressed and you have more energy in the spring—same thing in quantum dots. If you shrink the diameter of that quantum dot, the energy goes higher, which means that the light it emits becomes bluer. If you expand the diameter the color goes toward longer wavelengths.”

Ho observed that it’s possible to use the same semiconductor material to create crystals that emit virtually any color by simply changing the size of the crystals.

One of several quantum dot-powered displays shown at the 2015 CES

“That’s the benefit of quantum dots,” he said. “You can actually tune that wavelength.”

A second benefit comes from the fact that, while quantum dots are very narrowband emitters, they are broadband absorbers of light. When excited by high-energy ultraviolet or blue wavelengths, in falling back to their ground state, they give off the desired color as set by their physical size.

“They convert with almost 100 percent efficiency to the prescribed wavelengths of red or green, depending on their size,” said Ho. “The spectrum they emit is very pure.”

COLOR TV DISPLAY ADVANTAGES

It’s this very pure (narrowband) emission that makes quantum dot technology valuable in color television displays. In conventional LCD flat screens, a source of light is required behind the liquid crystal light valve. In some displays, light comes from a cold-cathode fluorescent emitter.

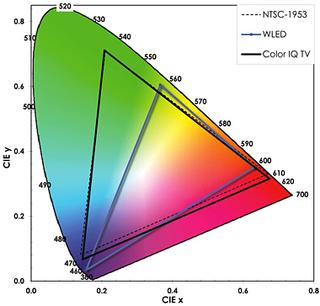

In more modern panels, the source of illumination has been from “white” LEDs. However, in terms of providing the colors needed to replicate the desired NTSC color gamut, such light sources leave a lot to be desired. The overall effect is shrinkage of the displayed gamut away from the chromaticity values established by CRT phosphor characteristics early in color television’s history.

“The reason the gamut is so small is that you have a blue LED with a yttrium aluminum garnet phosphor on top to create a white LED,” said Ho. “The resulting white spectrum is peaked around 540-550 nanometers, but is very broad. So you have a blue peak [along with] peaked up green or yellow. LCDs have filters for the backlight in the front panel and use [these] color filters to specify blue, green and red channels that are narrow so you can get pure primaries. However, filters aren’t perfect; if you have a very broad emitter, you have a lot more leakage between the blue and the green and the green and the red channels. When you start mixing these colors the gamut shrinks.”

According to Ho, to widen the color gamut of the display, you need to use an illumination source that has very precisely defined color emission—one providing very narrowband sources of red, blue and green. Quantum dots lend themselves to this application very nicely.

“To really extend the gamut back out, you want to start in the backlight with very narrow emitters,” said Ho. “The blue LED light source is acting as a narrow blue emitter and the green and red quantum dots are absorbing that and then re-emitting a very narrow green and red. This is the light that’s going through the front panel. The filters there don’t have to work as hard because there’s not as much leakage. You recover your pure green, pure red and pure blue. That allows you to get more than 100 percent of the NTSC gamut.”

EXCEEDING NTSC

The color television gamut as specified by the NTSC in 1953 versus what’s realizable with OLED and quantum dot display technologies. (Color IQ is a QD Vision trademark for quantum dot technology.)

According to Ho, there is a push in display technology to match the color gamut described by Michael Pointer, a researcher in color vision who developed a gamut of all the colors in nature that can be recognized by the human visual system.

“Pointer’s gamut represents all the naturally occurring colors in the world,” said Ho. “A gentleman named Pointer went around measuring things with a spectrometer and noticed many fell outside of the sRGB gamut standard [a color space developed by HP and Microsoft in 1996 for use in connection with color displays, printers and the Internet] and a lot fall outside of the NTSC [color television] gamut. So really Rec. 2020 [ITU-R Recommendation BT.2020, which defines various aspects of UHD television] is the only one that covers 99.9 percent of things, so that’s really what’s driving the move to larger and larger gamuts.”

Ho noted that while OLED goes further in presenting a wide gamut, it’s still limited and is also quite costly due to manufacturing yield problems. OLED has also had a difficult-to-solve problem with the longevity of its blue diodes that causes early failure of the displays. This is not a major problem with cellphone and tablet displays that are expected to last two or three years, but it is a much bigger concern with televisions and professional displays that are expected to last for five to 10 years. Quantum dots may offer a more cost-effective and reliable solution.

“For half the price of OLED technology, you’re getting even better color performance,” said Ho. “You can pay twice as much for an OLED, which is only showing you maybe 89 percent of the NTSC gamut, versus a television set that is showing 100 to 110 percent with quantum dots.”

APPLYING QUANTUM DOT TECHNOLOGY

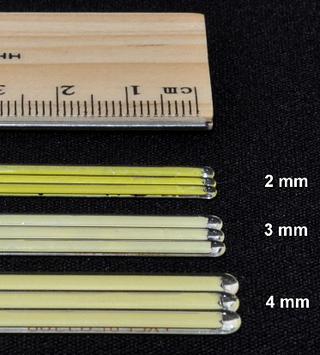

Ho explained that there are several methods for applying quantum dot technology to LCD panels, including films and encapsulated tubes of the material. His company has focused on the latter.

“We sell these glass tubes filled with quantum dots,” said Ho, holding up what appeared at first glance to be a large liquid-filled thermometer. “It looks yellow because of the red and green dots. The tube is hermetically sealed because quantum dots are sensitive to oxygen, and in the presence of light and heat they will degrade over time.”

He observed that the sealed tubes of quantum dot material (“ink” in the company’s vernacular) have a useful life of more than 30,000 hours, which is well in line with the lifetime of standard LCD TV displays. (Note that a display that’s turned on permanently will reach 30,000 operational hours in about 3.5 years.)

“We place these glass tubes on top of a blue LED bar and they get inserted at the edges of the TV display,” said Ho. “We can make the tubes as long as 1.3 meters if needed. They sit on the edges. Depending on configuration, this solution can add less than 10 percent to the overall price of the panel.”

Ho noted that using quantum dots in such a way [on the edge] requires very robust materials, as in such a configuration, they’re very close to the LEDs which are very bright and very hot.

“At this level you’re talking about 100 degrees Celsius and two Watts per centimeter-squared of flux; very, very intense—you couldn’t look at it.”

Ho stated that there’s a definite tradeoff in quantum dot display screen manufacturing technologies (tube vs. film).

Tubes of quantum dot material ready to be sent to display manufacturers

“You could also do it as a film to cover the entire screen with these quantum dots,” he said. “In doing so, you cut the intensity of the light by about 100 fold and reduce the temperature by about 50 degrees Celsius, so it’s a much nicer operating environment. You don’t need materials that are as robust. However, the challenge with a large-area film is that the oxygen barriers are very expensive. When you’re talking about a screen that’s about a meter square—a 55-inch TV set—you are going to be adding $100 to $200 in manufacturing costs to the TV.”

MADE IN AMERICA

Ho said that his company, QD Vision, which is based in Lexington, Mass., is the world’s largest manufacturer of quantum dot ink, keeping at least part of today’s television receiver jobs in America.

“The entire quantum dots are made in the U.S.,” said Ho. “You don’t need a lot of quantum dots to achieve the desired effect, but you do need some huge capital expenditures and a lot of equipment to service the entre TV industry.

“It’s called ‘ink’ as it’s made in solution with a special polymer that hardens with application of ultraviolet light. We ship our ink to Taiwan, because they have these old compact-fluorescent light making machines there that are able to fill glass tubes with whatever you want. They fill the tubes with the ink and photo-cure it to harden it and that’s the finished product. The tubes contain a solid rather than a liquid. We ship these completed tubes off to ‘brands’ where they are put into the TVs.”

WHAT’S NEXT?

When asked if the quantum dot technology might soon make its way into the very expensive, precise and stable color monitors required by the broadcast industry for quality control and color grading, he said there is now a lot of talk about this at present. However, the main thrust of the industry appears to be on consumer products.

“We’re democratizing this color performance and making sure that it gets in the hands of the consumers,” said Ho.

This article originally appeared in the Spring 2015 issue of the IEEE Broadcast Technology Society Newsletter and is used with permission.