Weathering Events with the Right Cables and Connectors

ALEXANDRIA, VA.— "Once a rodent finds a nice piece of cable to chew on, they'll spend all day and night at it," warns Fred Morgenstern, systems manager for Neutrik USA, a lead supplier of cables and connectors in the broadcast industry. To folks who make their living cabling outdoor events, this is just one of the many hazards they have to contend with on a daily basis.

Neutrik OptiCON Unlike the temperature and humidity-controlled environment of the typical broadcast facility, cables used in the field not only live a shorter life, but they face numerous challenges and threats posed by life in the great outdoors. For starters, they are subject to temperature extremes, dirt, moisture, EMI, corrosion, and even the danger of being eaten. Live outdoor events create a mission critical environment that requires special attention to detail in choosing the right equipment for the job. Not only do outdoor broadcasters (OBs) need cable that will coil back up in freezing temperatures, they need cable that can take a beating as well.

"Triax moving HD does not last as long as triax moving SD outdoors, and triax used on a golf course does not last as long as triax in a stadium due to golfers walking on it," says George Hoover, chief technology officer at NEP broadcasting, LLP. The Pennsylvania based mobile broadcaster who once needed a 52 foot semi-trailer to carry enough cable for an outdoor event is now able to do the same job today equipped with just a few baskets. Their success in this reduction of weight and cables is partly due to making the right choices in new cabling and connector technology.

A CLEAN CONNECTION

"The choice between copper and fiber depends upon the signal being transported, the I/O of the equipment in use, weight and distances to be run," explains Hoover. He says that most golf and auto racing connections outside the truck are done with fiber, due to distances and setup time. He finds smaller venues tend to use copper for their infrastructure because it is cheaper and simpler to maintain, but the larger the venue, the more apt they are to have to supplement with fiber.

The quality of the connections, whether copper or fiber, are as important as the cables themselves. "Because of the weather, the OB truck creates the harshest environment that our products are challenged to work in," says Mike Buchanan, vice president of patch panel manufacturer Bittree. "It is not just the temperature, but the changes between humidity that can affect connections."

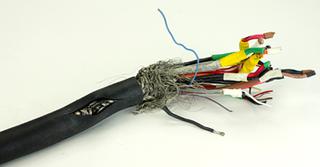

A damaged piece of cable taken from the end of a cable assembly. Video patchbays are mechanical switches, which have to be made of quality materials and properly plated with corrosion resistant metals to resist damage and prevent signal loss or failure. Good quality ones, if properly maintained, can even outlast the service life of the truck. Buchanan says that analog audio panels are typically more robust than video. "They are made with bigger internal springs that can take a lot of punishment," said Buchanan. He also acknowledged that OB trucks are moving to even higher density patch panels to support growing routers, which puts even more demand on the newer panels.

Whether connecting to patch panels or other cables, the connectors are often the most common cause of failure. From metallic corrosion to wet or dirty fiber ends, keeping cable ends protected is very important in outdoor conditions.

Neutrik developed a line of fiber-optic connectors call OpticonCON, which use a mechanical shutter on both the male and female ends of the connection to keep out dirt and limit moisture penetration. "Not everyone understands the fragility of the fiber connection," says Neutrik's Morgenstern. Often the protective plastic covers that come with the connectors are discarded or lost. By incorporating a built-in closing mechanism, the delicate fiber end is more easily kept clean when not attached to a panel or other connector. Manufacturers such as Fischer Connectors also offer outdoor solutions like their 1053 HDTV series, which provides field installable robust fiber optic terminations.

"The problem with copper connectors is that if moisture reaches the inner conductors, connector or dielectric, the characteristic impedance can change," says Daniel Collins, marketing manager for Clark Wire and Cable from Mundelein, Ill. He says that fiber is a better choice for outdoor usage as it lasts longer and it is easier to protect the inner fibers from moisture. For those applications where copper is needed, there is a wide array of tactical connectors. Taken from military specifications that require resilience in harsh environments, broadcasters are increasingly taking advantage of the benefits they provide. Clark sells tactical connectors for every type of cable from audio, to video and even data. Their DataTac RJ-45 connector system will allow more reliable data connections to be maintained in any outdoor environment.

Fischer Connectors 153 series provides field installable robust fiber-optic terminations.WHAT, THEY DON'T LAST FOREVER?

As a supplier of cables and connectors to a major Florida theme park, Neutrik's Morgenstern says "they have a shocking low life cycle due to warmth and humidity." The park typically replaces all outdoor cables every year to ensure no failures. OB truck operators also find that their cables have a limited lifespan. NEP's Hoover says that cables are always inspected and tested prior to every event for damage, but typically they don't last for more than a few years.

This is a dramatic difference from inter-facility wiring that usually remains intact until a change in signal type or bandwidth requires it to be replaced. Collins explains that "the most common sign that an outdoor cable needs to be replaced is a brittle or cracking jacket, but a cable that has been submersed in water, unless it's a special gel-filled type, needs to be considered for replacement." Thus, cables used for outdoor service, even if only occasionally, should be thoroughly monitored and if used for HD, replaced every few years.

SAFETY AND DURABILITY

Fiber optic cables continue to grow in popularity. From the benefit of being able to transport 12 cameras within a single run, and yet weigh a hundredth of its copper counterpart, it also offers a safety factor that hasn't gone unnoticed by outdoor broadcasters. The fact that glass and plastic do not conduct electricity makes the fiber ideal for the thousand yard runs lying out during a lightning storm. Not only can using fiber in this situation prevent equipment damage, but it can also prevent personal injury. An additional benefit for outdoor broadcasters is the fact that fiber is not affected by EMI, and unlike copper it will never act as an antenna.

Alas, there aren't any guaranteed mower proof cables available on the market yet, but manufacturers do have a broad selection of offerings that can provide a range of jacket strengths. New tactical cables are available with protective barriers that help protect from rodents, golf spikes, and other outdoor hazards. Finally, from special water resistant jackets and plastics that remain flexible in sub zero temperatures, to dust proof connectors, manufactures today are providing cable and connector options that enable greater coverage of outdoor events more successfully than ever before.

Get the TV Tech Newsletter

The professional video industry's #1 source for news, trends and product and tech information. Sign up below.