Tying It All Together

ALEXANDRIA, VA.

Perhaps the greatest improvement in video and audio cables in the last century was the development of lighter and more flexible cables. For anyone who has ever carried huge coils of multicore copper cable up a flight of stairs or tried to wrap a length of rigid 8281 coax through a plant, the more flexible and lighter cabling solutions developed in RG-6, RG-59 and Triax were a blessing. Distance had never been a huge issue in pre-digital days as analog signals traveled great distances and could always be boosted by a DA if needed.

Bend radius fibers enable much tighter bends without a discernable increase in attenuation. Then came digital equipment and signals, creating a moving target of cable options. Early adopters who wired their facilities with RG-59 based cables rated for 270Mbps digital signals had to rewire to RG-6 when HD arrived on the scene.

Now, with 1080p HD signals rapidly becoming the standard, some broadcasters are finding that the original specs for lengths of cables, type of connectors, and cable dressing of HD plants won't fully support the newer, higher bitrate HD signal on all paths. Add to this challenge, the fact that server-based technologies only run over fiber, and a broadcaster looking to upgrade or build a new facility will have to decide which type of cables and connectors is best.

So, should broadcasters be concerned about wiring their plants for the 3 Gbps high definition signal? Yes, according to Virginia-based systems integrator Humberto Irizarry, vice president with Innovative Technologies, Inc. in Chantilly, Va.

"3G-SDI signal infrastructure is needed to support 1080p, which is the future signal standard for new television facilities," explained Irizarry. He added that ITI is finding that many of its clients' analog and 270-Mbps-based plants are being upgraded to this new standard.

Cable manufacturers are finding that their client base is already ordering 3G-capable cabling, even if they are not currently using the standard.

"I have not run into many people who are using the SMPTE 424M standard in their plant," said Scott Fehl, a product manager for cable manufacturer Gepco in Des Plaines. "Most are more concerned that their infrastructure will handle it down the road."

COAX, FIBER, OR BOTH?

Belden 1347A cable "Coax is still the big winner in broadcast," says Steve Lampen, product line manager for cable manufacturer Belden's entertainment production in Richmond, Ind. He says that the big network facilities in New York are still using coax for most of their new runs. "Where fiber makes sense is between buildings, for very long runs, and as a backbone for some plant configurations," he said.

Dean Rosenthal, market manager for Broadcast, Entertainment and Enterprise Products at ADC in Minneapolis thinks copper is not going away and will always be a viable transport solution inside the facility and adds that any facility being built today should be done so with consideration of where fiber might make sense.

"Look how fast in the space of two years that 1080p became a market driver. The next step may be Super HD which will require fiber," he said

"Fiber will always do what it has always done well—transport signals long distances, provide wide bandwidth, and resistance to interference," Lampen said. Systems integrators, like Newington, Va.-based Communications Engineering, have discovered other reasons to consider fiber. "Fiber is being installed for density purposes," said Matt Weiss, senior managing engineer at CEI. "Clients often realize that they are trying to shoehorn a new 3G path into the limited space of an existing installation." He added that the density that bundled, or even single strand fiber can offer, is a significant space savings over similar copper paths.

For those involved in outdoor broadcasting (OB) like Telecast Fiber Systems, "The trend in our product offering is fiber multiplexing, with both TDM and CWDM solutions," said Gene Baker, CTO for the Worcester, Mass.-based company. "With lower cost transport methods like TDM, they see customers putting more signals over fewer signal paths, which is important on OB operations where a single run can be thousands of feet."

Another new trend is the use of cables with fewer internal fibers. "After watching the 12 strand cables being used in the field, we feel that 2-4 fiber cables make troubleshooting long, multi-cable paths much easier," Baker said. He observed in his field work that multiple signals sent over just a few paths were much faster to troubleshoot than tracing down a single bad fiber in a large bundle. With the difference in the cost of fiber and coax cable shrinking, customers can now choose the best option rather than the least expensive.

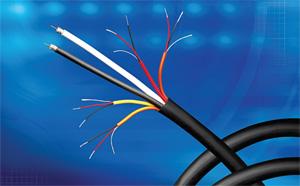

Also emerging in the broadcast/cable industry is the availability of not only custom-cable connections, but also connector types which can include both copper and fiber. Shane Colins, president of Clark Wire and Cable in Mudelein, Ind., says that their new Custom Select line of cables allows customers "to create almost any combination of cables including fiber, CAT5, coax, audio and power to make it their own." Such flexibility from manufacturers can be a bonus for broadcasters who want to consolidate cable runs in the field and throughout a facility.

Belden's new 1347A digital ENG cable was designed by network request. It houses two 1505A cables and four analog pairs. The smaller RG-59 video cabling was chosen to allow for more space and less weight on a reel. The analog audio lines are still considered the standard for field sound and IFB.

CONNECTING

Winchester EL-Series fiber optic video jack. When it comes to coax, the choices of connectors are fewer and more straightforward. Most broadcast video connections are made with a standard or mini BNC. The challenge in keeping 3G signal continuity has been to create a true 75 Ohm connector that is easily installed with consistent results. Major connector manufacturers like Kings, Trompeter, ADC, Canare, and Fischer now offer 3G rated connectors and provide technical documentation on the performance of their products.

For systems integrators who not only do many field terminations, but also fabricate large numbers of cables in their labs with automated equipment, standardization is key. "We often use ADC connectors based on tooling, inventory, and quality control," said CEI's Weiss. CEI bench-tested connectors from several top manufacturers prior to choosing the ADC units for its 3G installs.

Choosing a fiber connector is arguably more difficult. Not only are there different schools of thought between the broadcast manufacturers and those who use the products, but there are more options to select from as well as constantly improving versions of existing products. At the 2009 NAB Show, Winchester Kings introduced its new EL-Series fiber optic video jack designed to provide a more robust connection point. "The advantage of this design is that the optical fiber ends are easily maintained and more resistant to contamination in harsh environments than standard fiber optic interfaces," said Jerome Farnan, director of Fiber Optic Technology at Winchester Electronics in Wallingford, Conn.

Cable, connector, and panel manufacturer ADC is building its product lines around telco standard LC and SC connectors. LC connectors are smaller plastic connectors used in the IT/data business and often found on servers with multi-mode fiber connections. SC, a larger version of the LC, is popular with common carriers using single mode fiber and some broadcast manufacturers. ST was first adopted by broadcasters for single mode video fiber transmission and has both fans and detractors. Hardware companies like Evertz still offer these on outdoor and RF products, and Telecast's Baker believes they are still the best solution for the rigors of broadcast field work.

ADC's Rosenthal feels differently. "ST used to be the de facto standard, but they are pretty much gone now that the connector is coming to the end of its life in the telco community," he said. Rosenthal sees the larger carrier's phasing out of the connector as its death knell. He says ADC will focus on LC and SC interfaces as "there are so many improvements in these connectors' interoperability and loss budgets, and the new plastic housing is much more precise, making them the best choice."

Neutrik OpticalCON Baker likes a new LC connector developed by Neutrik for field work. "We are starting to see the emergence of Neutrik's OpticalCON," he said. "These connectors mount into the standard XLR hole on patch panels and not only offer fiber and copper connections, but have a system that helps protect these field patchable connections from becoming contaminated, which is one major issue with fiber connections."

TRENDS IN LAYING CABLE

The choice of cable type and connector is only the first part of a successful 3G cable path installation. The added bandwidth of 3G HD drives coax's signal-carrying ability to its limits. "Coax cable bundling and associated cable tray installation techniques are very important in the proper transmission of HD signals" said ITI's Irizarry.

Lampen has long been a staunch advocate for proper cabling techniques. "You can destroy a copper cable's ability to carry an HD signal very easily by putting wire ties on too tight or placing them the same distance apart creating periodicity," he said.

CEI's Weiss warns of similar hazards like "cable trays with evenly spaced rails and heavy cable loads [that] can compress bottom cables much in the same way a cable tie can."

Lampen pointed to a simple solution: "Go to Velcro ties or something that is soft and spreads the pressure out over the cable," he said. ITI has largely eliminated the use of hard cable ties in favor of the soft Velcro type according to Irizarry. CEI's Weiss says their procedures have not changed much, in that they have always been cautious in dressing cables appropriately, not over tightening cable ties, and by simply being conscious of the cable's bend radius.

Interestingly, cable manufactures themselves do not all agree on how much care should be taken during cabling. Gepco's Fehl says "Coax is not extremely delicate, but you don't want to be crushing [it] down with cable ties or placing all ties exactly the same distance apart."

Lampen has become an advocate for techniques long used in the data world; that is loosely draped random cables with a minimal of dressing intended to reduce the signal loss. "A messy installation works better than a neat one," he said. "This is depressing a lot of people who have spent a lifetime making beautiful installations." He reasons that it is more important that the signal get to its destination than having the installation look good.

"It's the new learning curve of what works and what doesn't, and setting up new rules for installations," noted CEI's Weiss. Whichever view wins out, it is a sure bet that people will be paying much closer attention to the practice over the next few years.

Get the TV Tech Newsletter

The professional video industry's #1 source for news, trends and product and tech information. Sign up below.