SolderBuddy

Good things do come in small packages, and I'm not speaking today of a box bearing a Tiffany & Co. label and containing some exotic form of carbon.

I recently received a 7-by-9-inch padded envelope containing an even smaller hardwood block which is very functional and useful, while at the same time, very simple in concept. It's one of those "why didn't I think of that" type of devices.

Those of us who have labored in the broadcast studio/transmitter/production house trenches can certainly appreciate its utility. How many times have you wished that you'd been born with a third arm and hand when it came time to solder audio connectors?

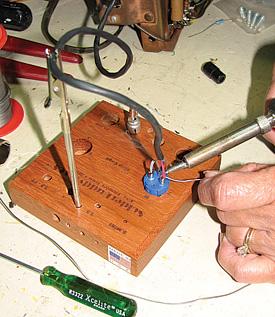

The SolderBuddy being used to prepare an XLR connector The SolderBuddy from Lee Tingler is that missing appendage. Its price is nowhere near what special custom-made clothing would cost if you were to be somehow equipped with a biological or bionic holding device either.

FEATURES

The SolderBuddy is constructed from a very solid (dense) piece of hardwood—mine was supplied in Brazilian cherry, but Tingler offers other woods as options. It comes with 12 holes precision machined into the front (top) surface and an additional four more on the rear. Also included is an alligator clip mounted on a 3-/4-inch piece of stiff tubing (more about which later). Labels are engraved into the wood via laser, and will not likely wear off or become obscured during the life of the device. (I have a feeling that the SolderBuddy will outlast most of its users and will be passed down to the next generation—if OSHA and the EPA haven't prohibited all soldering operations 30 or so years from now!).

I didn't try all of the supported connector possibilities, but the accompanying documentation says that the SolderBuddy works with 14 different types. There are places for male and female XLRs, RCAs, DINs, 1/4-inch and mini phone plugs, just to name a few. The alligator clip appendage fits snugly in one of the holes and plays the part of a third hand in securing oddball connectors that aren't directly supported by the collection of machined openings.

Despite its simplicity, the SolderBuddy is a well crafted and precise device, and not merely a random block of wood with a bunch of holes drilled in it by unskilled labor operating a 1/4-inch hand drill in the backside of someone's garage. The openings machined into the SolderBuddy are very accurate. (If you're considering bootlegging your own version after reading this review—don't. Unless you're a master craftsman with some amount of time to spend, you won't be satisfied with the results. At the price for which it's offered, the SolderBuddy is a bargain. It's not really worth the time and effort to try and cobble up your own.)

IN USE

I tried out the SolderBuddy in connection with a recent job in my "growing" home studio (actually a recreation of a 1950s/60s radio station, down to Ampex 350 and Magnecord PT-6 tape decks, along with a Mackenzie repeater, for those of you who were around when these were state-of-the art).

Of course there are a lot of XLR connectors and TRS plugs to be soldered in such an enterprise.

Several years ago, I got tired of splashing molten solder on workbench, floor and occasionally myself when I soldered such connectors in an "open air" fashion. This led to the purchase of a fairly expensive (several times the cost of the SolderBuddy) portable bench vise, complete with weighted base and padded jaws. Over the years, I've used this with some measure of success, but it's far from perfect. As the jaws are padded with a rubber-like material to keep from marring the connector undergoing cable attachment, the grip is not that firm and sometimes connectors can (and do) tilt just as the soldering iron tip is applied.

The SolderBuddy solves this problem handily with its custom created recesses for audio connectors. The male and female XLR spaces are especially good in this respect, as they include a keyway that precisely fits the locating pin on the connector body and firmly immobilizes the connectors when they are being soldered. Even the relative depths of the male and female XLR species have been compensated for in the creation of holes in the SolderBuddy.

My comfort level in attaching cables to XLRs was decidedly increased with the SolderBuddy. The wiring up of 1/4-inch TRS plugs went equally well.

I've never really been a fan of the RCA phono connector (what other audio connector breaks ground before breaking the "hot" conductor?) and only use them when I have to bring a consumer device into the "broadcast" environment. Nevertheless, I gave the SolderBuddy a chance to show me what it could do with RCAs, and the results—while not quite as nice as with XLRs and 1/4-inch phone plugs—were completely satisfactory. As the RCA is one of the few commonly used connectors (forgetting the old PL-239 "UHF" connectors, which fortunately aren't used for video anymore), that is wired by soldering a conductor within a hollow pin, the SolderBuddy's block, with its series of holes, doesn't support this first phase of RCA connector attachment. (It would have to have a hole drilled all the way through and be turned to an unstable position to do so.) This is one of the reasons that Tingler supplies the alligator clip appliance (it's referred to as the Post and Clip system). It's fitted firmly into the appropriate opening in the Solder-Buddy and nicely holds the RCA connector while heat and solder are applied to the long center pin. Once this is done (and the solder sets), the user can then insert the connector's center pin into the machined hole and solder the shield to the rear of the connector.

Fast Facts

Application

Broadcast studios, transmitter plants, production houses—anywhere electronic soldering operations are being performed.

Key Features

Accurately sized openings to firmly hold a variety of connectors when soldering, compact size and permanent lettering.

Price

MSRP $29.99 for "stock" model; units constructed with custom woods start at $45. Handling and shipping charges are extra.

Contact

Lee Tingler, Tingler Innovations

770-476-5337

www.solderbuddy.com

The alligator clip "stand" is also useful for wiring up other "oddball" connectors that don't fit into any of the SolderBuddy's holes. Some of my gear uses "Jones type" multipin plugs and sockets, and while the alligator clip device is useful for holding smaller Jones connectors, I have to admit that larger units are probably best handled in a regular bench vice due to their size and weight. But truthfully, how many of us still wire up Jones multipins (unless you've got a stable of Ampex and Magnecord recorders)?

All in all I was well pleased with the performance of the SolderBuddy.

SUMMARY

I've soldered on a lot of connectors during the past 50 years or so and have yet to find the perfect tool to replace that fabled third (non-heat conducting) hand. However, the SolderBuddy comes really close. It has caused me to completely give up on my expensive bench vice when it comes to wiring XLRs. I would highly recommend it to anyone who regularly wires audio connectors. (It's faster than opening and closing the jaws on a bench vise too.)

Could it be improved upon?

Perhaps slightly. Instead of the flat base, I would like to see a model with a mild forward tilt to provide a more natural angle for soldering some connectors. (This wouldn't be very hard to do in a later model.) Also, due to its very compact size—not much larger than the palm of your hand—I fear that if you are at all like me, it's going to be an easy tool to misplace, especially when working in a not especially well lighted equipment rack area, or just in the general clutter that finds it way to some workbenches. Until Tingler starts equipping his SolderBuddies with homing devices, I think that I'll dress mine up with some reflective tape or a touch of DayGlo paint just to make it stick out a little more. (By the way, Tingler says that he has perfected a mount for Jones connectors and will be offering it at some time in the future.)

Yes, good things can come in small packages. I wish that the SolderBuddy had been around years ago when I was cutting my teeth in this business.

Get the TV Tech Newsletter

The professional video industry's #1 source for news, trends and product and tech information. Sign up below.

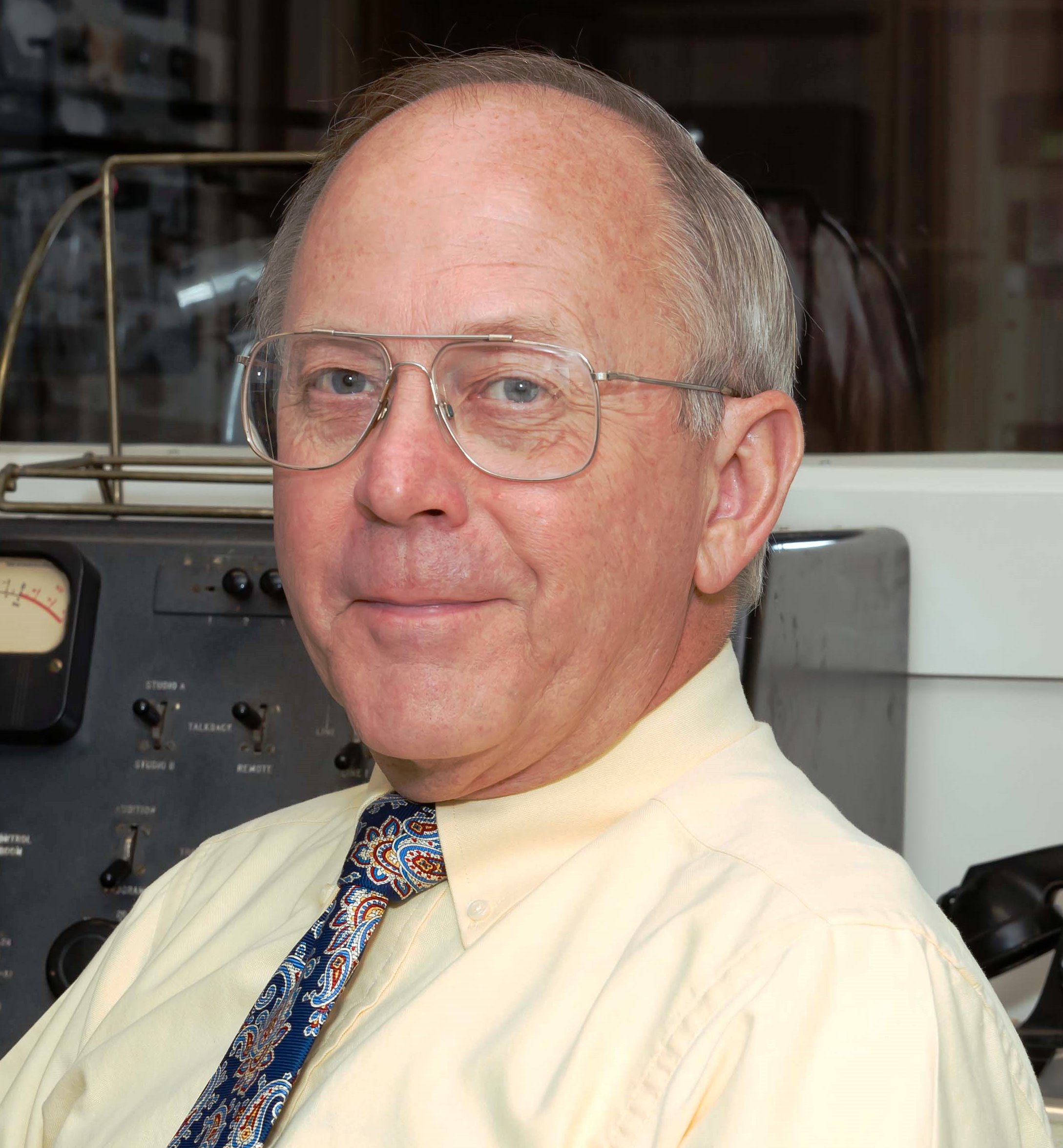

James E. O’Neal has more than 50 years of experience in the broadcast arena, serving for nearly 37 years as a television broadcast engineer and, following his retirement from that field in 2005, moving into journalism as technology editor for TV Technology for almost the next decade. He continues to provide content for this publication, as well as sister publication Radio World, and others. He authored the chapter on HF shortwave radio for the 11th Edition of the NAB Engineering Handbook, and serves as editor-in-chief of the IEEE’s Broadcast Technology publication, and as associate editor of the SMPTE Motion Imaging Journal. He is a SMPTE Life Fellow, and a Life Member of the IEEE and the SBE.